|

|

SRBH-1(20X) Pin Brinell

Hardness Tester

Features of Hammer Impact Brinell Hardness Tester

1. The hammer impact Brinell hardness tester works on Brinell

hardness testing principle. It applies the test force through hammer

impact, and achieves accurate control of test force with shear pin.

The Brinell hardness tester provides accurate test force, with high

uniformity and an error less than 0.5%.

2. The hardness testing device comes with the test force of 1580kg,

indenter diameter of 7.26mm, and F/D2 value of 30, the results of

which are equivalent to the standard testing conditions of 3,000kg

test force and ball with 10mm diameter.

3. The hammer impact Brinell hardness tester has high repeatability

and accuracy, with an error less than 5%.

4. This hammer impact hardness tester is fast, convenient, and easy

to operate, just by touching one side of workpieces.

5. The hammer impact Brinell hardness tester operates at low costs,

with the consumption of a single shear pin.

6. The hammer impact Brinell hardness tester has superior

reliability to that of the Leeb hardness tester.

Technical Parameter of Hydraulic Brinell Hardness Tester

Test Force :1,580kg

Indenter: 7.26mm Steel Sphere Indenter, test range 100~350HBW

4mm Hard Alloy Sphere Indenter, test range 350~650HBW

Indicator Error: ≤5%

Repeatability Error: ≤5%

Test Range: 100~650HBW

Net Weight: 0.8kg

|

Standard Assembly |

Optional Accessories |

|

7.26mm Steel Indenter

Shear Pin Housing

Housing

Handle

Brinell Hardness Block

Pin (250 pieces/box)

Pin Cleaner

20X Microscope with lighting

Carrying Case |

7.26mm Steel Sphere Indenter,

4mm Hard Alloy Sphere Indenter

Shear Pin Housing

Housing

Brinell Hardness Block

Pin (250 pieces/box)

20X Microscope

40X Microscope

Rechargeable Angle Grinder |

|

|

Hammer impact Brinell hardness tester applies test force by impact

hammer and accurately controls the force by shear pins. It pressed

the sample under the effect of hammering instantly. And the

indentation of measured diameter can be converted into Brinell

hardness value immediately. Our product is generally used to test

large and medium-sized castings, forgings, steels, nonferrous metals

as well as the semi-finished workpiece processed by quenching and

tempering heat treatments, so hammer impact Brinell type is suitable

for testing large forgings and castings with thick and big grains.

Hammer Brinell hardness type’s testing range is from 100 to 350HBW

when equipped with 7.26mm steel ball indenter while its testing

range is from 350 to 650HBW when equipped with 4mm steel ball

indenter. Compared with other impact types such as Shore type and

Leeb type, Brinell hardness type’s result is influenced little by

the outside factors, so its result is more stable and reliable.

Additionally, Hammer Brinell type can leave a permanent Brinell

hardness indentation which facilitates subsequent inspection and

testing. In addition, Hammer Brinell hardness tester has a simple

structure and cheap price and it is widely used in castings,

forgings, rollings, heat treatments and other industries in China

due to its simple structure and low price. |

|

|

|

|

Model SRBH-150(20X)

Pin Brinell Hardness Tester

Features of Pin Brinell Hardness Tester

1.It applies Brinell hardness test method, with static screw or

dynamic hammer impact loading test force, through a calibrated shear

pin to control the force precisely.

2.Good force value consistency, no influence by operator.

3.Test force F=1580kgf, diameter of test ball D=7.26mm, which leads

F/D2=30. It follows Brinell similarity principle, equals to normal

condition of 3,000kgf, 10mm test ball.

4.Good repeatability and high accuracy. The accuracy is the same as

desk tester.

5.Simple and flexible operation. Middle or small parts could apply

static force loading, and large part could apply hammer impact.

6.Only consume 1 piece of cheap shear pin for each test.

7.It could replace Leeb hardness tester in low accuracy and

reliability.

Technical Parameter of Pin Brinell Hardness Tester

Test Force 1580kg

Indenter: 7.26mm Steel Sphere Indenter, test range 100~350HBW

4mm Hard Alloy Sphere Indenter, test range 350~650HBW

Indicator Error: Static type ≤2~3% Comply with ISO, ASTM

Hammer Impact Type≤5%

Repeatability Error: Static type ≤2~3% Comply with ISO, ASTM

Hammer Impact Type≤5%

Test Range: 100~650HBW

Opening dimension: 150mm(Height) x100mm(Throat Depth)

Net Weight : 4.2Kg

|

Standard Assembly |

Optional Accessories |

|

Tester

7.26mm Steel Sphere Indenter

Shear Pin Housing

Flat Anvil

V-shape Anvil

Housing

Handle

Briness Hardness Block (HB10/3000)

Pin (250 pieces/box)

Pin Cleaner

20X Microscope with lighting

Rubber Protective Cover

Carrying Case |

7.26mm Steel Sphere Indenter,

4mm Hard Alloy Sphere Indenter

Pin (250 pieces/box)

Brinell Hardness Block (HB10/3000)

Sphere Spot Anvil (for pipe or curved plate)

Small Flat Anvil (for small parts)

20xMicroscope

40xMicroscope

Rechargeable Angle Grinder

PHB-10 Brinell Indentation Automatic Measurement System |

|

|

The

SRBH-150 Portable Brinell HardnessTester is designed following the

Brinell hardness test method. The test force is controlled by a

shear pin. After reading the diameter of the indention with the

reading microscope, the Brinell hardness value can be obtained from

the lookup table. The SRBH-150 Portable Brinell Hardness Tester has

two types of application: C clamp and hammer impact. It is capable

of testing from small to very large specimens. It is especially

suitable for assemblies inconvenient to be taken to the lab and not

allowed to be cut. The test can be completed in any direction to

test the hardness of upper, lower and lateral part of the specimen.

The test head itself can be used as a hammer impact tester. It can

perform the testing by touching one side of the work piece. Its

accuracy is much higher than any other type hammer impact tester.

According to the similarity principle of Brinell hardness testing,

with testing force of 1580kg, indenter diameter of 7.26mm, then F/D2=30. The test condition of the HB tester is equivalent to the

standard Brinell hardness test with 3000kgf and 10mm ball indenter.

The SRBH-150 Portable Brinell Hardness Tester can be widely used to

test the hardness of forgings, castings, steels, nonferrous metal

and its alloy products, and to test the hardness of annealed,

normalizing and tempered mechanical parts.

Compared to the Leed type hardness tester, the Brinell tester has

many advantages such as higher precision, fewer factors affecting

accuracy and lower requirement on the surface roughness. The test

result meets the requirements of most drawings without conversion

and is more widely accepted in the international business. |

|

|

|

|

Model SRBH-3000 Portable

Brinell Hardness Tester

Features of Hydraulic Brinell Hardness Tester

1.Test principle: Apply hydraulic principle permiting loading

3,000kgf manually.

2.On-site Testing: It could be applied in workshop, simple

operation, easy carrying, and testing body hardness of large parts

piece by piece.

3.Permanent Indentation: By 3,000kgf and 10mm test ball, the

indentation is permanent for re-inspecting.

4.High Reliability: It follows Brinell hardness test method

completely, the same as desk testers, reflecting the actual

mechanical property of material or parts.

5.High Accuracy: Indication error, repeatability error and test

force accuracy comply with ISO, and ASTM standards, the same as desk

testers.

6.Wide Application Range: As long as clamped to the parts, it could

test parts in any shape and size.

7.Wide Test Range:It

could test various common metal materials by its combination of

different test force and test head, that is, wide test range.

Technical

Parameter of Hydraulic Brinell Hardness Tester

Test Force: 3000kg

(1000kg, 750kg, 500kg optional)

Test Ball: 10mm Carbide alloy test ball

(5mm optional)

Test Range: 32~650HBW

Opening Dimension: 350mm (Height) x 100mm (Throat depth)

Indicator Error: complies with ISO 6506, and ASTM E10.

Repeatability Error: complies with ISO 6506, and ASTM E10.

Test Force Error: complies with ISO 6506, and ASTM E10.

Net Weight: 13.8kg

|

Standard Assembly |

Optional Accessories |

|

Tester

Handle

Brinell Hardness Block

Anvil (flat, V-type, spot-type )

20X Reading Microscope

10mm Spare Hard Alloy Test Ball |

Brinell Hardness Block (high or low value)

Hard alloy Test Ball (5mm, 10mm)

Spare Parts (Hydraulic oil capsule, Hydraulic oil, O-ring

etc.)

Maintaining Tools

Automatic Brinell Indentation Measurement System

Rechargeable Angle Grinder |

|

|

SRBH-3000 portable Brinell

hardness tester is the unique portable hardness tester in the world

which applies test condition with 3000kg test force on a 10mm

carbide indenter. It adopts hydraulic principle which functions the

hand-operated way to apply 3000kg test force. The central part of

SRBH-3000 is a small hydraulic system in which a release valve is

used to control the test force. When the force reaches 3000kg, the

release valve will open and the pressure will fall. As specified in

the operation manual, the tester needed to be forced to make the

indicator of the dial pointed at 3000kg test force for 3-5 times.

Thus it is equivalent to the test condition of Brinell hardness

testing method to hold 3000kg test force for 10 seconds with 10mm

steel ball, which complies with ASTM E110.The large indentation

resulted by the tester can reflect the average value of combined

influence affected by all the compositions of large materials. It is

unaffected by certain composition of materials or partial nonuniform

distribution and very suitable for testing nonuniform materials made

of large crystal particle. The testing result of this instrument is

true and accurate with good repeatability and it has a good

correspondence with tensile strength. It is the best mechanical

property tester can be used on site. The test condition and accuracy

meets the requirements of ISO 6506 and ASTM E110.

It can be used to test rough castings, forgings, nonferrous metals

and semi-finished products after tempering heat treatment. On-site

test of steel products, nonferrous metal, castings, forgings, and

semi-finished heat treatment parts. Applied to too large parts for

desk testers to test. Replace Leeb testers which are in low accuracy

and reliability. Indentation could be read by indentation automatic

measurement system and hardness valves displayed directly. |

|

|

|

|

Model SRBH-3000a

Chain

Hydraulic Brinell Hardness Tester

Features

1.On-site testing. It could be operated in workshop for its simple

operation, easy to carry, used in testing large cylinder workpiece

on site.

2.Permanent Indentation. Permanent indentation after test is for

rechecking.

3.High reliability. It completely follows Brinell hardness test

principle, reflecting the mechanical property of the test material

or parts, the same as desk tester.

4.High accuracy. The test force accuracy complies with relevant

regulations home and abroad, the same accuracy as desk tester,

complying with ISO ASTM standard.

Technical Parameter of Chain Hydraulic Brinell Hardness Tester

Test Force: 3000kg

(1000kg, 750kg, 500kg

optional)

Test Ball: 10mm Carbide alloy test ball

(5mm

optional)

Test Range: 32~650HBW

Test Diameter: ≤500mm

Indicator Error: complying with GB, ISO, ASTM

standards

Repeatability Error: complying with GB, ISO, ASTM

standards

Test Force Error: ≤±1%, complying

with GB, ISO, ASTM

standards

Net Weight: 14.5kg

|

Standard Assembly |

Optional Accessories |

|

Tester

Load Handle

Brinell Harness Block

20X Reading Microscope

10mm Spare Carbide Alloy Test Ball

Chain Measuring Frame

1.3m Chain

|

Brinell Hardness Block

(High

Value, Low Value)

Carbide Alloy Test Ball (5mm,10mm)

Maintaining Spare Parts (Hydraulic

Oil Capsule, Hydraulic Oil, O-Ring etc.)

Maintaining Tools

Other Specification Chains

Automatic Brinell Indentation Measuring System |

|

|

SRBH-3000a is a portable Brinell hardness tester has the same

structure as PHB-3000 hardness tester, in fact it is another type of

PHB-3000 with a chain. So It is also the portable hardness tester

which applies test condition with 3000kg test force on a 10mm

carbide indenter. It is consist of a test head and test frame. The

test head is a mini hydraulic system which contains a control valve

for controlling force. When force loading to 3,000Kgf, the control

valve opens, pressure releasing. According to ASTM standard, force

loading should be repeated 3 to 4 times, keeping the pin of the

pressure gauge reaching the point of 3,000Kgf 3 to 4 times. In this

way, it equals the test regulation of test force 3,000Kgf, 10mm test

ball, force maintaining time 10 to 14 seconds. The testing result

of this instrument is true and accurate with good repeatability and

it has a good correspondence with tensile strength. It is the best

mechanical property tester can be used on site. The test condition

and accuracy meets the requirements of ISO 6506 and ASTM E110.

It can be used to test rough castings, forgings, nonferrous metals

and semi-finished products after tempering heat treatment, On-site

testing of Steel Pipe, Bearings, Gas Cylinder. It can replace

inaccurate and unreliable Leeb hardness tester. The parts machining

and assembling quality of this instrument is much better than King

Brinell hardness tester. It is free of the problems of oil leak of

the hydraulic system and gear jamming of the jacking system, so it

has a higher cost performance. |

|

|

|

|

Model SRBH-750

Magnetic Hydraulic

Brinell Hardness Tester

Features

1.Test available if attached to one side of part.

2.No need to move the part.

3.No need to search for a spot for clamping.

4.Test condition of 5mm test ball, 750Kg test force, causes a larger

indentation and better representativeness and easier to read than

2.5mm test ball condition.

5.Compared with other hydraulic Brinell hardness testers, simpler

operation, easier to carry.

6.If surface available, test materials, parts and structural steel

in any shape and size.

Technical Parameter of Magnetic Hydraulic Brinell Hardness Tester

Test force: 750kg

Test ball: 5mm hard alloy ball

Test range: 100~650HBW

Indicator Error: complies with ISO 6506, and ASTM E10.

Repeatability Error: complies with ISO 6506, and ASTM E10.

Test Force Error: complies with ISO 6506, and ASTM E10.

Net Weight: 15.8kg

Surface: flat: area≥290mm x 90 mm

cylinder: diameter≥120mm

Standard Assembly

Tester

Load Handle

Pinch bar

Brinell Harness Block

Seat Iron

40X Reading Microscope

5mm Spare Carbide Alloy Test Ball |

|

SRBH-750

Magnetic Hydraulic Brinell Hardness Tester is consist of 2 magnetic

chucks and 1 hydraulic Brinell hardness test head, which is applied

to test body hardness of huge iron and steel work pieces on site.

The core part is a small hydraulic system. The operator could load

750kg test force by using the handle. There is a release valve to

control the test force. When the force reaches 750kg, the release

valve will open and close and then the pressure will fall down.

According to ASTM E110, it is kept loading to make the indicator of

the dial point at 750kg test force for 3-4 times altogether. Thus it

is equivalent to the test condition of Brinell hardness testing

method to hold test force for 10-15 seconds. The test condition of

the hardness tester is 5 diameter test ball and 750kg test force, so

the values of F/D2=30, of which the test result equals to the test

condition of 10mm test ball and 3,000kg test force. The method

complies with the regulation of ASTM E110. And the test accuracy

complies with regulations of ASTM E10 and ISO 6506.

It can only be applied in magnetic iron and steel work piece, not

those non-magnetic nonferrous metal, high manganese steel, wear

resisting cast iron and austenitic steel, etc.

It can be applied in testing flat surface work pieces and

mono-diameter cylinder work piece with diameter larger than 150mm by

specific customized cylinder adapters. If testing pipe materials,

the thickness of the shell of pipes should be larger than 15 to

20mm, depending on different diameters. It could test steel plates,

pipes, bars, moulds and huge castings, forgings, and heat treatment

work pieces as long as the test area is big enough. |

|

|

|

|

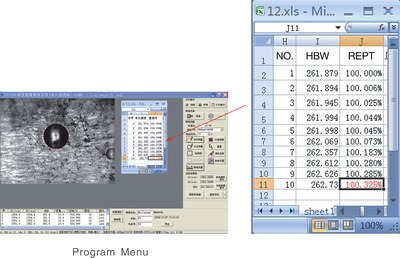

SRBH-10 Brinell

Indentation Automatic Measure System

Instrument Features

Advanced pattern recognition technology.

High definitional, fast gathering the figure signal of Brinell

indentation.

For the rather clear indentation, indentify it automatically and

display the diameter of indentation and Brinell hardness values

directly.

For unclear indentation on rough surface or incomplete one,

after gathering 3 points it gets diameter and harness values by

recovering the indentation.

Simple operation, easy carrying, applied in workshop on-site

test.

Automatically stock historical data, call at any time available.

Suitable for matching various portable Brinell hardness

testers.

Technical Parameters

Graphics resolution: 1024×768

Brinell test condition: Test force3000, 1500, 1000, 750, 500,

250, 187.5, 125, 100, 62.5, 1580Kg,

Diameter of test ball 10, 5, 2.5, 7.26, 4 mm

Test range: 8~650 HBW

Accuracy: 1% (HBW10/3000)

Standard Assembly

Lenovo Lap-top

Video cam sensor

Software disc

Special cable

Dongle

Carrying case

Attached files |

|

|

|

|

Model SRBH-3000D Electronic Brinell

Hardness Tester

Usage Range

The Brinell Hardness tester that shows the largest indentation among

all the hardness tests is able to reflect the comprehensive features

of the material ,and the test is unaffected by the organization

micro-dioptre and the compositional unevenness of the speciment ;and

hence it is a hardness testing with high precision. The Brinell

hardness test is widely used in such industrial fields as metallurgy

,forging ,casting ,unhardened steel and nonferrous metals

industries, as well as in the laboratories, universities ,colleges

and scientific research institutes.

Mains characteristic features

SRBH-3000D electronic Brinell Hardness Tester is a unified product

combining the precise mechanical structure with the computer control

by means of the mechanical and electrical circuit system, and so it

is the more advanced brinell hardness tester in today’s world. The

instrument adopts the motorized test force application without

weight blocks, and uses 0.5‰ accuracy compression sensor to feedback

the information and the CPU control system to automatically

compensate the test force lost during the testing. The test force

and the load dwell time can be directly set pressing the selected

keys on the touch-keyboard, with reliable repetition, precise

reading and easy operation.

Main

technical parameters:

|

Testing range: (8 - 650)HBW |

|

Test Force:

612.9N (62.5Kgf), 980N(100Kgf), 1226N(125Kgf),

1839N(187.5Kgf),

2452N(250Kgf), 4900N(500Kgf), 7355N(750Kgf), 9800N(1000Kgf),

14700N(1500Kgf), 29400N(3000kgf) |

|

Accuracy of Displayed Hardness Value |

|

Hardness Range(HBW) |

Max tolerance% |

Repetition% |

|

≤ 125 |

± 3 |

≤ 3.5 |

|

125<HBW≤225 |

± 2.5 |

≤ 3.0 |

|

>225 |

± 2.0 |

≤ 2.5 |

|

Max, Height of the speciment: 225mm |

|

Max Distance from the indenter center to the instrument

panel: 135mm |

|

Magnification of the microscope: 20X |

|

Min Reading Grade of the Drum wheel of the microscope:

0.005mm |

|

Power supply and Voltage: AC220V/50-60Hz |

|

Main Accessories:

Tables: Large, Small and V-shaped each;

Hard Alloyed Steel Ball Indenters: Φ2.5mm, Φ5mm, and Φ10mm

each.

One Microscope: 20X

Two Standard Hardness Blocks |

|

|

|

|

|

SRBH-3000M Digital Electronic Brinell Hardness Tester

Main

characteristic features:

SRBH-3000M Digital Electronic Brinell Hardness Tester is a unified

product combining optical, mechanic and electronic techniques, which

is adopted the precise mechanical structure and computer control

closed-circuit system. Without the weights, the instrument loads and

unloads the testing force with the motor. By means of the 0.5‰

accuracy compression sensor to feedback the information and the CPU

to control, the instrument compensates automatically the testing

force lost during the testing.

Equipped with a digital micro eyepiece on the instrument, the length

of indentation can be measured by this eyepiece directly. All

testing data such as the testing method, the testing force value,

the length of testing indentation, the hardness value and the dwell

time of testing force can be showed on the LCD screen, without

inputting the value of diagonal length for the indentation and free

from looking up the hardness value form the hardness table as well,

therefore the reading data are more accuracy and operation of this

instrument is more easy.

Technical Features and Standard Accessories:

Testing Range: (8

-

650) HBW

Test Force:

612.9N(62.5kg), 980N(100kg), 1226N(125kg), 1839N(187.5kg),

2452(250kg),

4900N(500kg), 7355N(750kg), 9800N(1000kg), 14700N(1500kg),

29400N(3000kg)

Max Height of the Specimen:225mm

Max Distance from the indenter Center to the Instrument Panel:135mm

Amplification of the Digital Micro Eyepiece:20×

Min. Graduation Value of the Drum Wheel of the Digital Micro

Eyepece:0.00125mm

Power Voltage:AC220V 50/60Hz

Main Accessories:

Testing Table: Large, Small and V-Shaped each 1 PC

Hard Alloyed Steel Ball Indenters:Φ2.5mm, Φ5mm, Φ10mm,each 1PC

One 15× Digital Micro Eyepec

Two Standard Hardness Blocks (HBW 3000/10 150-250)(HBW 750/5 75-125)

Weight 160kg (Gross Weight) 130kg(Net Weight)

Package Dimensions: 893×720×470(L×W×H)

|

|

|

|

|

Model TH600 Brinell Hardness Tester

Features:

-

Digital

Brinell hardness tester

-

Measuring the

Brinell hardness of unquenched steels,

-

Cast iron,

non-ferrous metals and soft bearing-alloys etc.

-

High testing

precision, extensive testing range, automatic load systemHigh

accuracy, wide measuring range.

-

Automatic

force loading.

-

Standards

conforming to: ASTM E-10, ISO6506.2

Technical Specification:

|

Test force |

1839N (187.5kgf),

2452N (250kgf), 7355N (750kgf),

9807N (1000kgf), 29420N (3000kgf) |

|

Indenter ball diameter |

2.5mm, 5mm and 10mm |

|

Test force dwell time |

6~99s adjustable |

|

Testing range |

8~650HBW |

|

Vertical testing space |

Max.230mm (9”) |

|

Horizontal testing

space |

Max.120mm (4.7”) |

|

Power supply |

220V/110V, 50~60Hz, 2A |

|

Net weight |

218kg |

|

Dimensions |

Max.730×230×890mm |

|

Standard delivery |

Main unit

Test block

20× microscope

Ф10mm hard alloy ball

indenter

Ф120mm round flat

anvil

Vee anvil

Power supply cable

Dustproof cover

Weight

Ground bolt |

|

Optional accessories |

φ2.5mm hard alloy ball

φ5mm hard alloy ball

φ10mm hard alloy ball

φ60mm anvil

φ70mm anvil

φ150mm anvil

Other test block

Ф2.5mm hard alloy ball

indenter

Ф5mm hard alloy ball

indenter

Ф80mm round flat anvil |

|

|

|