|

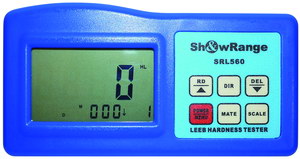

SRL560

SRL561 |

SRL560, SRL561 Leeb Hardness Tester

1.1 Typical Applications

* Die cavity of molds

* Inspection of bearing and other mass produced parts on a

production line

* Failure analysis of pressure vessel, steam generator and

other equipment

* Inspection of installed machinery, permanent parts of

assembled systems and heavy work pieces.

* Testing surface of a small hollow space

* Material identification in the warehouse of metallic materials

* Rapid testing in large range and multi-measuring areas for

large-scale work piece

1.2 Testing Features

* Palm size for narrow space.

* Test at any angle, even upside down.

* Direct display of hardness scales HRB, HRC, HV, HB, HS,

HL.

* Large memory could store 250 groups including single

measured value, impact direction, material and hardness

scale etc.

* User recalibration function allowed.

* Can communicate with PC computer for statistics and

printing by the optional cable.

* Manual or automatic shut down.

* Low battery indication.

1.3 Technical Specifications

Display: 12.5mm LCD with back light

Accuracy: Display error ±0.8% at LD=900

Measuring range: 200-900L

Conversion: HL-HRC-HRB-HB-HV-HSD

Materials: 9 different common materials

With USB interface

Memory: 250 data can be stored and re-readable

Impact device: D Will handle the majority of hardness testing

applications. Weight: 75g

Power supply: 2*1.5V AAA size battery

Dimension: 146*65*36mm

Weight: 130g (not including batteries)

Optional accessories: USB Cable & software, USB Cable &

software, Bluetooth data output |

|

|

|

|

Applications:

Applicable to Die cavity of molds,

Inspection of bearing and other mass produced parts on a production

line, Failure analysis of pressure vessel, steam generator and other

equipment, Inspection of installed machinery, permanent parts of

assembled systems and heavy work pieces, Testing surface of a small

hollow space, Material identification in the warehouse of metallic

materials, Rapid testing in large range and multi-measuring areas

for large-scale work piece. |

SRL580 Leed Hardness Tester

Features:

* Palm size for narrow space.

* Test at any angle, even upside down.

* Direct display of hardness scales HRB, HRC, HV, HB, HS,HL.

* Large memory could store 50 groups including single measured

value, impact direction, material and hardness scale etc.

* User recalibration function allowed.

* Can communicate with PC computer for statistics and printing by

the optional cable.

* Manual or automatic shut down.

* Low battery indication.

Specifications:

|

Case Material |

Aluminum Alloy |

|

Display |

LCD |

|

Materials |

9 different common materials

( Steel & Cast Steel, Metallurgy tool steel, Forged

Steel, Gray Cast Iron, Nodular Cast Iron, Cast

Aluminum, Brass, Bronze, Copper ) |

|

Measuring range |

(170-960) HLD, (20-68) HRC,

(19-651) HB, (80-967) HV, (30-100) HS, (13-100) HRB |

|

Accuracy |

±8HLD(HLD=800) |

|

Repeatability |

±6HLD(HLD=800) |

|

Conversion |

HL-HRC-HRB-HB-HV-HSD |

|

Measuring Direction |

360° |

|

Impact device |

D Will handle, Weight: 75g |

|

Radius of Measured Work

piece |

Rmin=50mm ( For non-conventional Supporting

ring Rmin=10mm ) |

|

Min. Weight of Work piece |

Stable support 2kg (

0.1kg Coupling ) |

|

Min. Thickness of Work

piece |

3mm |

|

Min. Thickness of Hardened

Layer |

0.8mm |

|

Working Conditions |

Temperature: 0~40ºC

Humidity: ≤ 90% |

|

Power supply |

2 * 1.5 V AA size (UM-3)

battery |

|

Dimension |

130 * 76 * 31 mm |

|

Weight |

340g (Not Including

Batteries) |

Standard Accessories:

1. Main Unit

2. Standard Test Block

3. Measurement Sensor

4. Carrying Case

5. Operation Manual

6. Small Support Ring

7. Cleaning brush

Optional Accessories:

1. Impact Body

2. Support Rings set

3. USB data cable with software

4. Bluetooth data out put with software |

|

|

|

|

|

SRL510 Leeb Hardness Tester

Specification

1.Measuring Method; Leeb Hardness Testing

Method

2.Hardness Scale; HL, HB, HRB, HRC, HV, HS, σb

3.Measuring range; HLD (200-960) HRC (19.8-68.5) HRB (13.5-100)

HB (30-651) HV (80-976) HS (26.4-99.5) σb (375-2639).

4.Impact device:D type impact device(Standard), Optional

C/G/DC/DL/D+15 .

5.Accuracy; ±6HLD (HLD=800),Repeatability: less than 6HLD (HLD=800)

6.Measuring Direction; 360 degree by manual setting

7.Material; Steel & Cast Steel, Stainless Steel,, GC IRON, NC IRON, Cast

Aluminum alloy, Macht metal, Copper-tin alloy,Brass

Resolution; 1HL, 1HV, 1HB, 0.1HRB, 0.1HRC, 0.1HS

8.Display; LED with backlight

9.Memory; 100groups (each group include1-7 testing result and

1 AVE value)

10.Communication; USB port(Standard)and Blue tooth(Optional)

11.Printer; Thermal Printer with blue tooth(optional)

12.Power; Two 1.5V AA batteries

13.Working temperature; -10 to+50ºC

14.Size; 153mm×76mm×37mm (H×W×D)

15.Weight; 280g including batteries.

Standard delivery

LM100main unit, D type Impact

Device, Standard Test Block, Protective rubber Sheath, Small Supporting

Ring, Cleaning Brush, 2 AA batteries, User's Manual, DataView

Software, Instrument Case.

Optional accessories:

Impact device: D/C/G/DC/DL/D+15/G,

Standard Test Block, Blue Tooth Module &Thermal Printer, Belt,

Standard Support Ring, Small Support Ring,

Special Support Ring |

|

|

|

|

|

SRL530, SRL533 Leeb Hardness Tester

Operating Principle

The impact body,which is equipped with

tungsten carbide,impact velocities are measured at the 1mm point

from the work piece in the following way: the integrated permanent

magnet will produce directly proportional voltage with the impact

velocity.The Leeb hard-ness values are calculated by the following

formula: HL=1000X(Vb/Va).

|

Instrument Specifications |

|

Display Type |

1.77 inch OLED with resolution 160x128 pixels |

|

Hardness Scale |

HL, HB, HRB, HRC, HV, HS. σb. |

|

Measuring Range |

HLD (200-960) HRC (19.8-68.5) HB (30-651) HV

(80-976) HS (26.4-99.5) HRB (13.5-100) .σb.(375-2639) |

|

Impact Device |

D type impact device (Standard); Optional DL type impact device(Only SRL533) |

|

Accuracy |

±6HLD (HLD=800), Repeatability ﹤6HLD (HLD=800) |

|

Measuring direction |

360 degree by manual setting |

|

Material |

Steel& Cast Steel, Stainless Steel, GC IRON, NC IRON, Cast Aluminum alloy, Macht metal,

Copper-tin alloy, Brass, Forged Steel |

|

Resolution |

1HL, 1HV, 1HB, 0.1HRB, 0.1HRC, 0.1HS |

|

Calibration |

Automatic |

|

Language |

English, Chinese |

|

Memory: |

1000 groups ,each group include 6 testing result and 1 average value(Only SRL533) |

|

Communication |

USB port, used for recharging and data transmission

((Only SRL533)) |

|

Software |

LmVIEW Software for transmission, storage, and printing (Only SRL533) |

|

Power |

AAA Polymer lithium battery ,Capacity of 600 MA/H,voltage:3.7 V, warning under low voltage |

|

Instrument Shut-off |

AUTO OFF after 3 minutes of inactivity |

|

Temperature |

-10ºC~ +50ºC |

|

Net Weight |

110g with D type impact device,125g with DL type impact device |

|

Size |

150mm*46mm*23mm |

|

Standard |

GB/T 17394-1998, ASTM A956 |

Standard delivery

Main unit(With D type impact device),

HLD value Standard Calibration Block, DataView software,

USB Communication cable, Small supporting ring,

Cleaning brush, Recharger,

User's manual,

Suitcase.

Optional accessories

Impact device DL,

Standard calibration test block,

Standard supporting ring, Special supporting rings, Small supporting ring |

|

|

|

|

Main Function

Parameters:

1. Choose Testing

Materials, Hardness Scales, Measuring Direction and times of Tests

By Button;

2. Direct Display of Hardness Scales including HRB, HRC, HV, HB, HS,

HL

3. Show the Result of

Each Test Repeated, Automatically or Manually Remove the Wrong Test

Results;

4. Directly Output the Average Single Test Result or All the Results

In One Time;

5. Automatic detection of the Battery Voltage, Low Voltage Warning

for Battery protection, With Battery Indicator Icon in Test Status;

6. Instant Reporting;

7. Plenty of status bar display, displaying Bluetooth, buzzer, error

information, time, battery quantity and so on.

|

SRL001 Leeb

Hardness Tester

Instant report

printing

With ultra-low power consumption

Features:

Suitable for multiple impact device and 6 types of hardness scales

are available for various applications

Embedded thermal printers, instant test report printing

Large and clear digital display

Rechargeable lithium ion battery , support USB charging

Supporting Bluetooth transmission and wireless printing

Standard delivery with PC software+USB

cable

with perfect data base function. Supporting

data query, system characteristics displaying and bar graph

displaying

Technical Specification:

Hardness scales: HL, HRC, HRB, HV, HB, HS

Test precision: HLD: +/-4 HRC: +/-1 HB: +/-4

Standard impact device: impact device of Type D

Upper / lower limits setting: (170~960)HLD

Optional impact device: D/ C /DC / D+15 / DL/ G

Number of impact devices Equipped with one time: any

PC Interface: USB2.0

Screen display: 128X64 dot matrix LCD, backlight and adjustable

contrast

Measuring direction:360°(Test at any angle even upside down)

Data memory :100 readings

Maximum hardness of the measured work: 940HV(for D, DC, DL, D+15, C

impact device)

Radius of curvature of the measured work: Rmin=50mm(If using Alien

Supporting ring, Rmin=10mm)

Recognition function: Recognize the type of the impact device by

itself

Type of the printer: Embedded thermal printers

Measurable material: Steel and cast steel, alloy tool steel,

stainless steel, gray cast iron, nodular cast iron, aluminum casting

alloy, copper zinc alloy (brass), copper tin alloy (bronze), fine

copper

Detecting voltage automatically: auto-alarm automatically when

working voltage is less than rated voltage

Power: Rechargeable lithium ion battery of 3.7v, 2200mAh

Charger: 5V USB charging

Shape size: 78×87×40mm

Weight: 320g

Packing: 1PCS/CTN, CTN SIZE: 33*20*10CM,

G.W.: 4KGS

Wireless transmission: Supporting Bluetooth transmission and

wireless printing

|

|

|

|

|

Main function

parameters:

1. Choose Testing Materials, Hardness Scales, Measuring Direction

and times of Tests By Button;

2. Direct Display of Hardness Scales including HRB, HRC,HV, HB, HS,

HL

3. Show the Result of Each Test Repeated, Automatically or Manually

Remove the Wrong Test Results;

4. Directly Output the Average Single Test Result or All the Results

In One Time;

5. Automatic detection of the Battery Voltage, Low Voltage Warning

for Battery protection, With Battery Indicating Icon in Test Status;

6. Plenty of Status Bar Display, Displaying Bluetooth, Buzzer, Error

Information, Time, Battery Quantity and so on. |

SRL003 Leeb Hardness Tester

Li-ion Battery Powered

with USB charging

Features:

Ultra-thin shell, more easily to hold

Suitable for multiple impact device and 6 types of hardness scales

are available for various applications

Large and clear digital display

Rechargeable lithium ion battery , support USB charging

Standard delivery with PC software+USB

cable with perfect data base function. Supporting

data query, system characteristics displaying and bar graph

displaying

Technical Specification:

Hardness Scales: HL, HRC, HRB, HV, HB, HS

Test Precision: HLD: +/-6 HRC: +/-1 HB: +/-4

Standard Impact Device: impact device of Type D

Upper / Lower Limits Setting: (170~960)HLD

Optional Impact Device: D/ C /DC / D+15 / DL/ G

Number of Impact Devices Equipped With One Time: any

PC Interface: USB 2.0

Screen Display: 128X64 dot matrix LCD, backlight and adjustable

contrast

Measuring Direction: 360°(down, inclined down, level, inclined up

and up)

Data Memory: 100 readings

Maximum Hardness of The Measured Work Piece: 940HV(for D, DC, DL,

D+15, C impact device)

Radius of Rurvature of The Measured Work: Rmin=50mm(If using Alien

supporting ring, Rmin=10mm)

Recognition Function: Recognize the type of the impact device by

itself

Measurable Material: Steel and cast steel, alloy tool steel,

stainless steel, gray cast iron, nodular cast iron, aluminum casting

alloy, copper zinc alloy (brass), copper tin alloy (bronze), fine

copper

Power Supply: rechargeable lithium ion battery of 3.7v, 800mAh

Charging Mode: USB charging

Shape Size: 175×77×35mm

Weight: 220g

Packing: 1PCS/CTN, CTN SIZE: 33*20*10CM,

G.W.: 4KGS |