|

SRUF100H series Handheld Ultrasonic

Flow Meter |

|

¡¡

Handheld Flow Meter |

¡¡

Transducer |

|

Instructions:

The SRUF100H ultrasonic flow meter

is designed to measure the fluid velocity of liquid within a

closed conduit. The transducers are a non-contacting, clamp-on

type, which will provide benefits of non-fouling operation and

easy installation.

The SRUF100H transit time flow meter utilizes two transducers

that function as both ultrasonic transmitters and receivers. The

transducers are clamped on the outside of a closed pipe at a

specific distance from each other. The transducers can be

mounted in V-method where the sound transverses the pipe twice,

or W-method where the sound transverses the pipe four times, or

in Z-method where the transducers are mounted on opposite sides

of the pipe and the sound crosses the pipe once. This selection

of the mounting method depends on pipe and liquid

characteristics. The flow meter operates by alternately

transmitting and receiving a frequency modulated burst of sound

energy between the two transducers and measuring the transit

time that it takes for sound to travel between the two

transducers. The difference in the transit time measured is

directly and exactly related to the velocity of the liquid in

the pipe

Features:

* Better than 1% accuracy;

*

0.2% of repeatability;

*

4*16 English letters LCD display;

*

Operate with clamp on transducers;

*

RS 232 interface or 1-channel isolated OCT output;

*

Pipe diameters from 15mm to 6000mm;

*

Ni-MH battery operation of over 12 h;

*

90~230VAC power supply;

*

Internal data logger;

*

Bilingual interface in Chinese and English.

Specifications:

|

Repeatability |

Better than 0.2% |

|

Accuracy |

¡À1% of reading at rates>0.2 mps |

|

Response Time |

0-999 seconds, user-configurable |

|

Velocity |

¡À32 m/s |

|

Totalizer |

7-digit totals for net, positive and negative flow

respectively |

|

Liquid Types |

Virtually all liquids |

|

Security |

Setup values Modification Lockout. Access code needs

unlocking |

|

Display |

4x8 Chinese characters or 4x16 English letters, display

instant flow, velocity, total flow, signal status

|

|

Signal output |

Non-isolation RS232(FUJI extension protocol), one

channel isolation OCT output |

|

Transducers |

Clamp on type transducers |

|

Transducer Cord Length |

Standard 2*10 meters, optional 2*500 meters

|

|

Power Supply |

3 AAA Ni-H built-in batteries. When fully recharged it

will last over 12 hours of operation. 100V-240VAC for

the charger |

|

Data Logger |

Built-in data logger can store over 2000 lines of data

|

|

Housing Material |

ABS |

|

Case Size |

100*66*20mm |

|

Handset Weight |

514g (1.2 lbs) with batteries |

¡¡

|

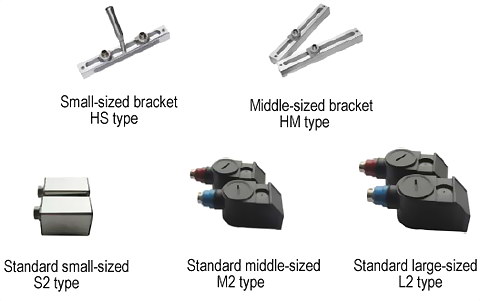

Transducer |

HS type |

HM type |

Standard S2 type |

Standard M2 type |

Standard L2 type |

|

Suitable pipe size (mm) |

DN15-100 |

DN50-700 |

DN15-DN100 |

DN50-DN700 |

DN300-DN6000 |

|

Suitable pipe size (inch) |

1/2~4" |

2~28" |

1/2~4" |

2~28" |

12~240" |

|

Material |

Aluminum alloy |

Plastic

alloy |

|

Work Frequency |

1MHz |

|

Installation Method |

V (N, W) |

V, Z |

V (N, W) |

V, Z |

Z |

|

Calibration |

Calibrate with the main unit |

|

Magnetism |

Magnetic |

|

Fluid temperature |

0¡ãC~160¡ãC |

|

Outer size (mm) |

200*25*25 |

280*40*40 |

45*30*30 |

71*37*40 |

91*52*44 |

|

Weight |

250g |

1080g |

75g |

259g |

535g |

|

Liquid types |

Water, sea water, waste water, chemical liquids, oil,

crude oil, alcohol, beer, etc. |

|

Suspension concentration |

¡Ü20000ppm, may contain very small amount of air bubbles. |

|

Pipe material |

All metals, most plastic, fiber glass, etc. |

|

Dedicated shielded transducer cable |

Standard length 5 meter x 2, can be extended to 10 meter

x 2 |

¡¡

Model Selection Guide:

|

SRUF100H-Transducer type-Cable length |

|

SRUF100H |

Handheld flow meter |

|

Transducer type: |

HM: HM-type

HS: HS- type

S2: S2- type

M2: M2- type

L2: L2-

type

|

|

Cable length |

5: 5 meter (standard cable length) |

For example:

SRUF100H-S2+M2+L2-5: The handheld flow

meter, should configure S2, M2, L2 transducer, cable length is 5

meter.

Standard configuration:

|

|

¡¡ |

|

SRUF200H Handheld Ultrasonic Flow Meter

Features:

High Accuracy: Accuracy: ¡À1%, linearity: 0.5%, repeatability: 0.2%

Wide measuring range: Several types transducer for selection, pipe

size from Dn15mm to Dn6000mm

Large capacity battery: Built-in rechargeable Ni-MH battery, provide

over 12 hours of continuous operation

Non-intrusive measuring: Non-intrusive , clamp on transducer, no

pressure drop, no pipe disturbance

Support Multiple language Menu: Chinese, English, Italian and other

languages can be customized

Large LCD display: Display instantaneous flow, accumulated flow

(positive, negative and net), velocity, working status etc.

Built-in data logger: Built-in 24K data logger, store over 2000

lines measuring data

Liquid Type

This flow meter can be virtually applied to a wide range of

measurement. A variety of liquid applications can be accommodated:

ultra-pure liquids, potable water, chemicals, raw sewage, reclaimed

water, cooling water, river water, plant effluent. etc

Applications:

Water supply and drainage, Heating,

Construction of Energy-saving, Metallurgy, Petrochemical and Power.

Measuring Diagram:

|

Clamp on |

Mounting Bracket |

|

|

|

Specifications:

|

Item |

Performance and Parameter |

|

Convertor |

Principle |

transit-time ultrasonic flow meter |

|

Accuracy |

Flow: over 1%-2%(battery-powered supply over ¡À2%),

Heat: over ¡À2%,

Repeatability: over 0.2% |

|

Display |

4*1 6 character LCD with backlight, support the language of

Chinese, English and Italy |

|

Signal Output |

1 way OCT pulse output( Pulse width 6 ~ 1000ms,

default is 200ms) |

|

Data interface |

Insulate Rs232 serial interface, upgrade the flow meter

software by computer |

|

Pipe Condition |

Pipe Material |

Steel, Stainless steel, Cast iron, Copper, Cement pipe,

PVC, Aluminum, Glass steel product, liner is allowed.

|

|

Pipe Diameter |

25~-6000mm |

|

Straight length pipe |

Transducer installation should be satisfied: upstream10D,

downstream 5D, 30D from the pump. |

|

Measuring Medium |

Type of Liquid |

Water (hot water, chilled water, city water, sea water,

waste water, etc.); Sewage with small particle content; Oil

(crude oil, lubricating oil, diesel oil, fuel oil, etc.);

Chemicals (alcohol, acids, etc.); Plant effluent; Beverage,

liquid food; Ultra-pure liquids; Solvents and other liquids |

|

Temperature |

Standard Transducer: -30~90¡ãC; High-temperature transducer:

-30~140¡ãC

|

|

Turbidity |

Under 10000ppm and less bubble |

|

Flow rate |

0~¡À7 m/s |

|

Working Environment |

Temperature |

Main Unit: -20~60¡ãC

|

|

Flow transducer: -40~160¡ãC;

Temperature transducer: according to the customer¡¯s demands.

|

|

Humidity |

Main Unit: 85% RH Flow Transducer: Ip67 |

|

Power Supply |

3 AAA built-in Ni-MH batteries 1.2V(for over 12 hours of

operation). 90V-260V AC adapter |

|

Power Consumption |

1.5W |

Optional Transducer:

|

Clamp on Transducer |

Clamp on sensor with the magnet, you can install the

transducer very easily when measuring the carbon steel

pipes and iron pipes, no need to cut off water and no

pressure loss |

|

Mounting Bracket Transducer |

The fixtures and slides adopt full aluminum material,

with the feature of light weight and firm structure. The

Metric/British system scale can improve installation

accuracy.¡¡

|

Model Selection Guide:

SRUF200H - Optional Transducer - Cable

length (5: 5m*2 (Standard)/ 10: 10m*2)

For example:

SRUF200H+TM-1+10m = SRUF200H (convertor) + TM-1 + 5M*2 cable +

Stretcher+ Couplant (1pc)+ Carrying case + Ruler |

|

¡¡ |

SRUF100M series Modular Ultrasonic

Flow Meter

Technology features:

1. Operating power: isolation 8-36VDC

2. Current: 50mA(under the condition of connection without

keyboard display and sound of buzzer)

3. Signal output: one channel standard isolation RS485

output One channel isolation 4-20mA or 0-20mA passive

output. Two channel OCT output (programmed between the pulse

width(6-1000ms),default before leaving factory (200ms))

4. Signal input: two channel three wire system PT100

platinum resistor input loop, to make heat meter has the

function of displaying heat quantity. Three channel 4-20mA

input optional,accuracy:0.1%,has the ability to input the

signals of pressure, liquid level, temperature and so on.

5. Display: 2*10 backlit LCD, displaying instant flow rate,

velocity, positive, negative, net totaliser flow rate.

6. Operating: 4 keypad tactile keyboard operating

7. Other functions: automatic memory the positive, negative,

net totaliser or flow rate and heat quantity of the last 512

days,128 months,10years Automatic memory the time of power

on/off and flow rate of the last 30 times, realize to

replenish by hand or automatically, read the data through

Modbus communication protocol.

8. Protection level:IP57

9. Transducer: clamp-on type, insertion type, in-line type.

Optional accessory:

1. Clamp-on transducer

(standard S2 type, standard M2 type, standard L2 type)

¡¡

¡¡

|

Transducer |

Standard S2 type |

Standard M2 type |

Standard L2 type |

|

Suitable pipe size (mm) |

DN15-DN100 |

DN50-DN700 |

DN300-DN6000 |

|

Suitable pipe size (inch) |

1/2~4" |

2~28" |

12~240" |

|

Material |

Plastic alloy |

|

Work Frequency |

1Hz |

|

Installation Method |

V (N, W) |

V, Z |

Z |

|

Calibration |

Calibrate with the main unit |

|

Magnetism |

Magnetic |

|

Fluid temperature |

0¡ãC~160¡ãC |

|

Protection class |

IP68 (can be work under

water, water depth ¡Ü3m) |

|

Outer size (mm) |

45*30*30 |

71*37*40 |

91*52*44 |

|

Weight |

75g |

259g |

535g |

|

Liquid types |

Water, sea water, waste water, chemical liquids,

oil, crude oil, alcohol, beer, etc. |

|

Suspension concentration |

¡Ü20000ppm, may contain very small amount of air

bubbles. |

|

Pipe material |

All metals, most plastic, fiber glass, etc. |

|

Dedicated shielded transducer cable |

SEYV75-2 special shielded transducer cable, can

be extended to 500 meter for per cable (Contact

us for longer cable requirement) |

¡¡

2. Insertion transducer

(standard insertion B, cement insertion B)

|

|

Insertion B type (insert directly)

|

Insertion B type (for cement pipe)

|

|

Suitable diameter |

Above DN80mm |

Above DN80mm |

|

Installation room |

¡Ý550mm |

¡Ý700mm |

|

Fluid temperature |

-40¡ãC-160¡ãC |

-40¡ãC-160¡ãC |

|

Transducer material |

316L

stainless steel |

316L

stainless steel |

3. In-line type transducer (¦Ð

type, standard type)

|

|

¦Ð-type

transducer |

Standard type |

|

Material |

Stainless steel |

Carbon steel (stainless steel is optional) |

|

Pipe

size |

DN15-DN40mm |

DN50-DN6000mm |

|

Connection: |

Flange type |

Flange type |

|

Application of temperature |

-40¡ãC~160¡ãC |

|

Protection class |

IP68(can work in water, and water depth¡Ü3

meter) |

|

Rated pressure |

Please

refer to table 1 |

|

Dimension |

Please

refer to following table 1 |

Table 1

|

Nominal |

Rated |

¦Ð-type |

Standard-pipe |

Flange dimension (mm) |

|

Diameter (mm) DN |

Pressure

(Mpa) |

L1 |

L2 |

D |

D1 |

D2 |

f |

N-¦µ |

Flange thickness |

|

15 |

2.5 |

320 |

- |

95 |

65 |

45 |

2 |

14*4 |

14 |

|

20 |

360 |

- |

105 |

75 |

55 |

2 |

14*4 |

16 |

|

25 |

390 |

- |

115 |

85 |

65 |

3 |

14*4 |

16 |

|

32 |

450 |

- |

140 |

100 |

76 |

3 |

18*4 |

18 |

|

40 |

500 |

- |

150 |

110 |

84 |

3 |

18*4 |

20 |

|

50 |

1.6 |

- |

200 |

160 |

125 |

100 |

3 |

18*4 |

22 |

|

65 |

- |

200 |

180 |

145 |

120 |

3 |

18*4 |

24 |

|

80 |

- |

225 |

195 |

160 |

135 |

3 |

18*8 |

24 |

|

100 |

- |

250 |

215 |

180 |

155 |

3 |

18*8 |

26 |

|

125 |

- |

250 |

245 |

210 |

185 |

3 |

18*8 |

28 |

|

150 |

- |

300 |

280 |

240 |

210 |

3 |

23*8 |

28 |

|

200 |

- |

350 |

335 |

295 |

265 |

3 |

23*12 |

30 |

|

250 |

- |

450 |

405 |

355 |

320 |

3 |

25*12 |

32 |

|

300 |

- |

500 |

460 |

410 |

375 |

4 |

25*12 |

32 |

|

350 |

- |

550 |

520 |

470 |

435 |

4 |

25*16 |

34 |

|

400 |

- |

600 |

580 |

525 |

485 |

4 |

30*16 |

38 |

|

400 |

1.0 |

- |

600 |

565 |

515 |

482 |

4 |

25*16 |

30 |

|

450 |

- |

700 |

615 |

565 |

532 |

4 |

25*20 |

30 |

|

500 |

- |

800 |

670 |

620 |

585 |

4 |

25*20 |

32 |

|

600 |

- |

1000 |

780 |

725 |

685 |

5 |

30*20 |

36 |

|

700 |

- |

1100 |

860 |

810 |

775 |

5 |

24*25 |

32 |

|

800 |

- |

1200 |

975 |

920 |

880 |

5 |

24*30 |

32 |

|

900 |

- |

1300 |

1075 |

1020 |

980 |

5 |

24*30 |

34 |

|

1000 |

- |

1400 |

1175 |

1120 |

1080 |

5 |

28*30 |

36 |

4. Remote second times operation

meter (wall-mounted type, panel-mounted type)

5. PT100 there wire platinum resistor (used for heat meter)

6. Strap (applied with installation of transducers on cast

iron, GRP, PVC, etc. that can not be welded directly.

7. Special shielded twisted pair cable

8. Ultrasonic thickness gauge (measure the thickness of

pipe, reduce error, increase accuracy)

Model Selection Guide:

SRUF100M A - B +

C + D + E + F - G - H - I

|

Letter |

Parameter |

Option |

|

A |

Main board version |

Version-18 |

|

B |

Display terminal |

N: none (power supply for module is: 8~30VDC)

S: the panel mount (power: 85~264VAC or 24VDC)

F: the plastic wall mount (power: 85~264VAC or

24VDC) |

|

C |

Power |

A: AC 85-264VAC (for the display terminal)

D: DC 24VDC (for the main unit) |

|

D |

Transducer |

B: 1: S2-type Clamp-on transducer for small pipe

2: M2-type Clamp-on transducer for middle pipe

3: L2-type Clamp-on transducer for

large pipe

C: 1: B-type insertion wetted transducer

2: Cement insertion wetted transducer

G: Pipe transducer (lea then DN40 use the

PI-type transducer, more than DN50 user the

Standard-pipe transducer) |

|

E |

Pipe size |

DN(mm)- |

|

F |

Pipe material |

0: Carbon steel

1: Stainless steel

2: Cast iron

3: FRP

4: PVC

5: Cement |

|

G |

Nominal pressure |

Mpa |

|

H |

Signal output |

N: None

A: 4-20mA output (note range)

F: OCT output

4: RS485 output (note baud rate, communication

check digit) |

|

I |

Signal input |

N: None

1: one channels 4-20mA analog input

2: two channels 4-20mA analog input

3: three channels 4-20mA analog input |

|

J |

Cable (single cable length) |

Meter, (pipe type is four-core cable, others are

two-core cable) |

For

example:

SRUF100M18-N-B2-300-2-1.6-N-N-10:

The version-18 ultrasonic flow module, no display terminal,

M2-type clamp-on transducer, pipe size is DN300, pipe

material is cast

iron, nominal pressure is 1.6Mpa, no output

and input, cable is 10 meter x 2

|

|

SRUF200S series Separated Ultrasonic

Flow meter

Features:

High Accuracy: 1%

Wide measuring range: Several types transducer for selection, pipe

size from Dn15mm to Dn6000mm

High Reliability: Adopt low voltage, multi-pulse technology to

improve accuracy, operation life and reliability.

Strong Anti-interference: Dual-balance signal differential

receiver/driver circuit to avoid interference of converter, TV

tower, high voltage line etc.

Powerful Recording Function: Automatically record the following

data:

1. The totalizer data of the last 512 days/128 months/10 years

2. The time and corresponding flow rate of the last 6 4 times of

power on and off events

3. The working status of the last 32 days

Support Heat Measurement: Connect the temperature transducer ,can

finish the heat/energy measurement

Support SD card Memory: Optional SD card

Liquid Type:

This flow meter can be virtually applied to a wide range of

measurement. A variety of liquid applications can be accommodated:

ultra-pure liquids, potable water, chemicals, raw sewage, reclaimed

water, cooling water, river water, plant effluent. etc.

Measuring Diagram:

¡¡

Optional Main unit:

According to different installation

condition, there are two models separated ultrasonic flow meter for

selection:

|

Wall-mount |

Panel-mount |

|

Wall mounted SRUF200SW

Indoor or instrument box installation

Dimension:170*180*56mm

Power supply:DC8~36V or AC85~264V |

¡¡

¡¡

Panel mounted SRUF200SS

Instrument Cabinet installation

Dimension:170*180*56mm

Hole-opening dimension:156*76mm

Power supply:DC8~36V or AC85~264V |

Optional Transducer:

|

Clamp on Transducer |

Clamp on sensor with the magnet, you can install the

transducer very easily when measuring the carbon steel

pipes and iron pipes, no need cut off water and no

pressure loss |

|

Insertion Transducer |

No need to cut off water, no pressure loss; Stable and

reliable for long term operation with good signal¡¡

|

|

Pipe Transducer |

Need to cut off water, no pressure loss; With high

accuracy and stability and good signal |

Specifications:

|

Item |

Performance and Parameter |

|

Convertor |

Principle |

transit-time ultrasonic flow meter |

|

Accuracy |

Flow: over 1%-2%(battery-powered supply over ¡À2%),

Heat: over ¡À2%,

Repeatability: over 0.2% |

|

Display |

2*20 character LCD with backlight, support the language of

Chinese, English and Italy Convertor

dimension:170*180*56cm |

|

Operation |

Support 16 key light touch keyboard and the Simulation

keyboard software |

|

Signal Output |

1 way 4~ 20mA output, electric resistance 0~ 1K,

accuracy0. 1% |

|

1 way OCT pulse output( Pulse width 6 ~ 1000ms,

default is 200ms) |

|

1 way Relay output |

|

Signal Input |

3 way 4~ 20mA input, accuracy 0. 1%,

acquisition signal such as temperature, press and liquid

level |

|

Connect the temperature transducer Pt100, can finish the

heat/energy measurement |

|

Data interface |

Insulate RS485 serial interface, upgrade the flew meter

software by computer, support the MODBUS, METER-BUS etc.

|

|

Other Function |

Automatically remember the previous flew/energy data of

512 days, 128 months and 10 years |

|

Automatically remember the previous flew/energy data of

512 days working condition and check it |

|

Automatically remember the previous 32 times power on/off

time and flow rate |

|

Special Cable |

Twisted-pair cable, generally, the length under 50 meters;

Select the RS485 communication. The transmission

distance can over 1000m. |

|

Pipe Condition |

Pipe Material |

Steel, Stainless steel, Cast iron, Copper, Cement pipe,

PVC, Aluminum, Glass steel product, liner is allowed.

|

|

Pipe Diameter |

25~6000mm |

|

Straight length pipe |

Transducer installation should be satisfied: upstream10D,

downstream 5D, 30D from the pump. |

|

Measuring Medium |

Type of Liquid |

Water (hot water, chilled water, city water, sea water,

waste water, etc.); Sewage with small particle content;

Oil (crude oil, lubricating oil, diesel oil, fuel oil,

etc.); Chemicals (alcohol, acids, etc.); Plant

effluent; Beverage, liquid food; Ultra-pure liquids;

Solvents and other liquids |

|

Temperature |

Standard Transducer: -30~90¡ãC;

High-temperature transducer: -30~140¡ãC

|

|

Turbidity |

No more than 10000ppm and less bubble |

|

Flow rate |

0~¡À7 m/s |

|

Working Environment |

Temperature |

Main Unit: -20~60¡ãC

|

|

Flow transducer: -40~160¡ãC;

Temperature transducer: according to the customer¡¯s

demands. |

|

Humidity |

Main Unit: 85% RH; Flow Transducer: IP67 |

|

Power Supply |

DC 24V or AC 85-264V |

|

Power Consumption |

1.5W |

Model Selection Guide:

SRUF200S - Convertor- Flow Transducer-

DN__mm - Pipe Material -- Pressure (Mpa) - Cable length (m) - Temp

Transducer-----SD card Memory

W

TS-2

0: Carbon

Steel

None

0: Yes

S

TM-1

1:

Stainless Steel

CT-1

1: No

TL-1

2:

Cast iron

TCT-1

TS-2-HT

3: Glass Fiber reinforced

PCT-1

TM-1-HT

4: PVC

SCT-1

TL-1-HT

5: Cement

TC-1

6: Others

TC-2

G

For example:

SRUF200SW+TM-1+DN300+0+1.6MPa+ 10m+ PCT-1+0 = SRUF200SW (convertor)

+ TM-1 + 5M cable * 2 + Steel belt (DN300) + Couplant (1pc) + PCT-1 |

|

¡¡ |

|

SRUF200F Integrated Ultrasonic Flow

meter

Features:

High Accuracy: 1%

Wide measuring range: Several types transducer for selection, pipe

size from Dn15mm to Dn6000mm

High Reliability: Adopt low voltage, multi-pulse technology to

improve accuracy, operation life and reliability.

Strong Anti-interference: Dual-balance signal differential

receiver/driver circuit to avoid interference of converter, TV

tower, high voltage line etc.

Powerful Recording Function: Automatically record the following

data:

1. The totalizer data of the last 512 days/128 months/10 years

2. The time and corresponding flow rate of the last 6 4 times of

power on and off events

3. The working status of the last 32 days

Support Heat Measurement: Connect the temperature transducer ,can

finish the heat/energy measurement

Liquid Type:

This flow meter can be virtually applied to a wide range of

measurement. A variety of liquid applications can be accommodated:

ultra-pure liquids, potable water, chemicals, raw sewage, reclaimed

water, cooling water, river water, plant effluent. etc.

Measuring Diagram:

¡¡

Optional Transducer:

|

Clamp on Transducer |

Clamp on sensor with the magnet, you can install the

transducer very easily when measuring the carbon steel

pipes and iron pipes, no need cut off water and no

pressure loss |

|

Insertion Transducer |

No need to cut off water, no pressure loss; Stable and

reliable for long term operation with good signal¡¡

|

|

Pipe Transducer |

Need to cut off water, no pressure loss; With high

accuracy and stability and good signal |

Specifications:

|

Item |

Performance and Parameter |

|

Convertor |

Principle |

transit-time ultrasonic flow meter |

|

Accuracy |

Flow: over 1%-2%(battery-powered supply over ¡À2%),

Heat: over ¡À2%,

Repeatability: over 0.2% |

|

Operation |

Support 4 keyboards magnetic bar/simulation keyboard

software |

|

Signal Output |

1 way 4~ 20mA output, electric resistance 0~ 1K,

accuracy0. 1% |

|

1 way OCT pulse output( Pulse width 6 ~ 1000ms,

default is 200ms) |

|

1 way Relay output |

|

Signal Input |

3 way 4~ 20mA input, accuracy 0. 1%,

acquisition signal such as temperature, press and liquid

level |

|

Connect the temperature transducer Pt100, can finish

the heat/energy measurement |

|

Data interface |

Insulate RS485 serial interface, upgrade the flew meter

software by computer, support the MODBUS, METER-BUS etc.

|

|

Other Function |

Automatically remember the previous flew/energy data of

512 days, 128 months and 10 years |

|

Automatically remember the previous flew/energy data of

512 days working condition and check it |

|

Automatically remember the previous 32 times power

on/off time and flow rate |

|

|

|

|

Special Cable |

Twisted-pair cable, generally, the length under 50

meters; Select the RS485 communication. The transmission

distance can over 1000m. |

|

Pipe Condition |

Pipe Material |

Steel, Stainless steel, Cast iron, Copper, Cement pipe,

PVC, Aluminum, Glass steel product, liner is allowed.

|

|

Pipe Diameter |

25---6000mm |

|

Straight length pipe |

Transducer installation should be satisfied:

upstream10D, downstream 5D, 30D from the pump.

|

|

Measuring Medium |

Type of Liquid |

Water (hot water, chilled water, city water, sea water,

waste water, etc.); Sewage with small particle content;

Oil (crude oil, lubricating oil, diesel oil, fuel oil,

etc.); Chemicals (alcohol, acids, etc.); Plant

effluent; Beverage, liquid food; Ultra-pure liquids;

Solvents and other liquids |

|

Temperature |

Standard Transducer: -30--90¡ãC ; High-temperature

transducer: -30--140¡ãC |

|

Turbidity |

No more than 10000ppm and less bubble |

|

Flow rate |

0~¡À7 m/s |

|

Working Environment |

Temperature |

Main Unit: -20~60¡ãC |

|

Flow transducer: -40~160¡ãC ;

Temperature transducer: according to the customer¡¯s

demands. |

|

Humidity |

Main Unit: 85% RH; Flow Transducer: IP67 |

|

Power Supply |

DC 24V or AC 85-264V |

|

Power Consumption |

1.5W |

Model Selection Guide:

SRUF200F - Flow Transducer- DN__mm -

Pipe Material -- Pressure (Mpa) - Cable length (m) - Temp Transducer

TS-2

0: Carbon

Steel

None

TM-1

1:

Stainless Steel

CT-1

TL-1

2:

Cast iron

TCT-1

TS-2-HT

3: Glass Fiber reinforced

PCT-1

TM-1-HT

4: PVC

SCT-1

TL-1-HT

5: Cement

TC-1

6: Others

TC-2

G

For example:

SRUF200F+TM-1+DN300+0+1.6MPa+10m+ PCT-1 = SRUF-200F(convertor)+ TM-1

+ 5M cable *2 + Steel belt (DN300 ) + Couplant(1pc) + PCT-1 |

|

¡¡ |

|

Flow Transducer for SRUF200 series

1. Clamp on flow transducer:

Standard clamp on flow transducer:

|

Picture |

Description |

Model |

Measuring Range |

Temperature Range

|

Dimension |

|

|

Small size Clamp on transducer |

TS-2 |

DN15~DN100mm |

-30~90¡ãC |

45*25*28mm |

|

Medium size Clamp on transducer |

TM-1 |

DN50~DN700mm |

-30~90¡ãC |

64*39*44mm |

|

Large size Clamp on transducer |

TL-1 |

DN300~DN6000mm |

-30~90¡ãC |

97*54*53mm |

High temperature clamp on flow transducer:

|

Picture |

Description |

Model |

Measuring Range |

Temperature Range

|

Dimension |

|

|

High temp small size Clamp on transducer |

TS-2-HT |

DN15~DN100mm |

-30~160¡ãC

|

45*25*28mm |

|

High temp medium size Clamp on transducer |

TM-1-HT |

DN50~DN700mm |

-30~160¡ãC

|

64*39*44mm |

|

High temp large size Clamp on transducer |

TL-1-HT |

DN300~DN6000mm |

-30~160¡ãC

|

97*54*53mm |

2. Mounting Bracket Transducer:

|

Picture |

Description |

Model |

Measuring Range |

Temperature Rang |

Dimension |

|

|

Small size bracket transducer |

HS |

DN15~DN100 |

-30~90¡ãC

|

318*59*85mm |

|

|

Medium size bracket transducer |

HM |

DN50~DN300 |

-30~90¡ãC

|

568*59*85mm |

|

|

Extended bracket transducer |

EB-1 |

£¾DN300

|

-30~90¡ãC

|

88*59*49mm |

|

|

High temperature small size bracket transducer

|

HS-HT |

DN15~DN100 |

-30~160¡ãC

|

318*59*85mm |

|

|

High temperature medium size bracket transducer

|

HM-HT |

DN50~DN300 |

-30~160¡ãC

|

568*59*85mm |

|

|

High temperature extended bracket transducer

|

EB-1-HT |

£¾DN300

|

-30~160¡ãC

|

88*59*49mm |

3. Pipe transducer:

|

Picture |

Description |

Model |

Measuring Range |

Temperature

Range |

Dimension |

|

|

¦Ð type |

G3 |

DN15~DN25 |

-30~160¡ãC

|

304 stainless steel threaded connection |

|

|

standard |

G2 |

DN32/DN40 |

-30~160¡ãC

|

carbon steel threaded connection |

|

|

standard |

G1 |

DN50~DN1000 |

-30~160¡ãC

|

carbon steel flange connection |

4. Insert Ultrasonic Transducer:

|

Picture

|

Description

|

Model

|

Measuring Range

|

Temperature Range

|

Dimension

|

|

|

Standard

|

TC-1

|

DN80~DN6000

|

-30~160¡ãC

|

190*80*55mm

|

|

Lengthen

|

TC-2

|

DN80~DN6000

|

-30~160¡ãC

|

335*80*55mm

|

|

|

Parallel

|

TC-3-1

|

DN300~DN500

|

-30~160¡ãC

|

97*54*53mm

|

|

TC-3-2

|

DN501~DN800

|

-30~160¡ãC

|

45*25*28mm

|

|

TC-3-3

|

DN801~DN6000

|

-30~160¡ãC

|

64*39*44mm

|

¡¡

Temp Transducer for SRUF200 series:

1. Clamp on temperature transducer:

|

Picture |

Description |

Model |

Measuring Range |

Temperature

Range |

Dimension |

Accuracy |

|

|

Three-wired system PT100 |

CT-1 |

¡ÝDN50 |

-30~160¡ãC

|

64*39*44mm |

100¡ãC¡À0.8¡ãC

|

|

Two-wired system PT1000 |

CT-2 |

¡ÝDN50 |

-30~160¡ãC

|

64*39*44mm |

2. Insertion temperature

Transducer with pressure

|

Picture |

Description |

Model |

Measuring Range |

Depth |

Temperature

Range |

Installation Requirement |

|

|

Three-wired system PT100

with pressure |

PCT-1 |

DN50~DN150

|

210mm

|

-30~160¡ãC |

No need to cut off water |

|

DN200~DN250

|

250mm

|

-30~160¡ãC |

|

¡ÝDN300 |

340mm

|

-30~160¡ãC |

|

Two-wired system PT1000

with pressure |

PCT-2 |

DN50~DN150

|

210mm

|

-30~160¡ãC |

No need to cut off water,

mainly used for battery

powered ultrasonic flow meter |

|

DN200~DN250

|

250mm

|

-30~160¡ãC |

|

¡ÝDN300 |

340mm

|

-30~160¡ãC |

3. Insert temperature transducer

|

Picture |

Description |

Model |

Measuring Range |

Depth |

Temperature

Range |

Installation Requirement |

|

|

Insertion PT100/PT1000

Small size pipe diameter |

SCT-1 |

£¼DN50

|

30mm

|

-30~160¡ãC

|

Need to cut off water |

|

|

Insertion temperature

Transducer Pt100 |

TCT-1 |

DN50~DN150

|

105mm

|

-30~160¡ãC

|

|

DN200~DN250

|

140mm

|

-30~160¡ãC

|

|

¡ÝDN300 |

210mm

|

-30~160¡ãC

|

|

Insertion Pt100

Installation with pressure |

TCT-2 |

DN50~DN150

|

210mm

|

-30~160¡ãC

|

Need to cut off water, mainly used for battery powered

ultrasonic flow meter |

|

|

¡¡ |