|

Model: XK3190-A9

Introduction:

Weighing indicator XK3190-A9 adopts high precision double integral

A/D conversion technology, widely applied in electronic floor scale,

electronic truck scale, static railroad scale and so on alike static

weighing system equipped with 1~8 load cell.

Features:

- A/D conversion with readability 1/30000

- Use inner code to replace weight observing and analysis tolerance

- Zero range setup (auto/manual)

- Fast filled weighing bill print setup

- Save 255 vehicle ID/net weight, 100 cargo ID, and 205 weighing

records

- Weighing data save protection in case of power off

- Battery indication and low battery protection

Parameters:

|

Model |

A9 |

A9P |

|

Input signal

range |

1mV~24mV |

|

Input

sensitivity |

−1μV/e |

|

Load cell

Excitation |

Dc 8V |

|

Max. load

cell connection |

8 at 350 ohm |

|

Display |

7 bits LED ,7

status indications |

|

Standard

interface |

RS232C serial

communication,

Scoreboard at 20mA current loop

Parallel printer |

|

Model: XK3190-D2+

Introduction:

- Double integral A/D conversion technology

- Multi-functions and strong adaptability

-Applied in floor scale, truck scale, static weighing system with

1~8 load cell

Features:

- A/D conversion with readability 1/30000

- Zero range setup (auto/manual)

- Auto/manual, daily/sorted report print setup

- Fast filled weighing bill print setup

- Save 255 vehicle ID/net weight, 100 cargo ID, and 512 weighing

records

- Weighing data save protection in case of power off

- Manual linearity-correction calibration

- Max. 5-point non-linearity correction

Parameters:

|

|

|

|

|

|

|

|

|

|

|

|

|

Max. load

cell connection

|

|

|

|

6 bits

VFD, 6 status indications

|

|

|

|

|

|

RS232C serial

communication,

Scoreboard at 20mA current loop

Parallel printer |

|

|

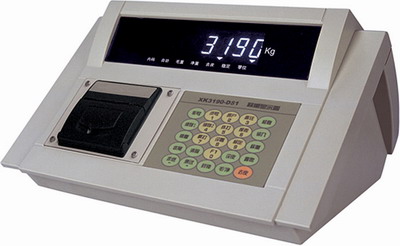

Model: XK3190-DS1

Introduction:

- Applied in floor scale, truck scale, weighing system with 1~16

load cell

Features:

- Connect with digital load cell

- Auto/manual angel correction

- Railway scale correction

- Use inner code to replace weight observing and analysis tolerance

- Zero range setup (auto/manual)

- Non-linearity and calibration tolerance correction

- Password management and timing power off function

- Auto/manual, condition/non-condition, daily/sorted report print

setup

- Fast filled weighing bill print setup

- Save 1500 vehicle ID/net weight, 201 cargo ID/cargo name, 100

customer ID/customer name, 100 notes and 1501 weighing records

- Weighing data save protection in case of power off

- Input character with keyboard or download from PC

- Modify communication address of digital load cell Data check for

single load cell and single angle

Parameters:

|

|

|

Digital

load cell connection

|

|

Load cell

connection distance

|

|

|

|

|

Max. load

cell connection

|

|

|

|

7 bits

VFD, 7 status indications

|

|

|

RS232C

serial communication,

Scoreboard at 20mA current loop

Parallel printer

|

|

|

RS232C |

|

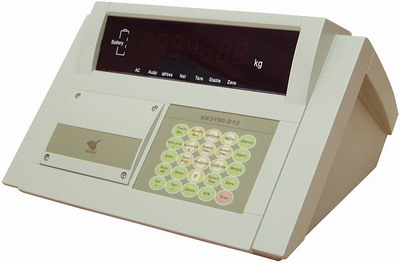

Model: XK3190-D10

Introduction:

Weighing indicator XK3190-D10 adopts high precision ‘-∆

A/D conversion technology, widely applied in electronic floor

scale, electronic truck scale, static railway scale and so on, alike

static weighing system equipped with 1~8 load cell.

Features:

- A/D conversion with readability 1/30000

- Use inner code to replace weight observing and analysis tolerance

- Zero range setup (auto/manual)

- Non-linearity and calibration tolerance correction

- Password management and timing power off function

- Auto/manual, condition/non-condition, daily/sorted report print

setup

- Fast filled weighing bill print setup

- Save 1500 vehicle ID/net weight, 201 cargo ID/cargo name, 100

customer ID/customer name, 100 notes and 1501 weighing records

- Weighing data save protection in case of power off

- Input character with keyboard or download from PC

- Good consistency

- Hardware detection and voltage display of load cell signal

Parameters:

|

Model |

D10 |

D10P |

|

Input signal

range |

-30mV~30mV |

|

Input

sensitivity |

−1μV/e |

|

Load cell

Excitation |

Dc 5V |

|

Max. load

cell connection |

8 at 350 ohm

or 16 at 700ohm |

|

Display |

7 bits LED, 7

status indications |

|

Optional

interface |

|

|

|

Model: XK3190-DS2

Introduction:

- 32-bits fast speed and high performance ARM processor

and effective

- convenient character input and personal operating

window

-Applied in static weighing system equipped with 1~16

digital load cell

Features:

- Connect with digital load cell

- Auto/manual angel correction

- Use inner code to replace weight observing and analysis tolerance

- Password management and timing power off function

- Auto/manual, daily/sorted report print setup

- Fast filled weighing bill print setup

- Save 1000 vehicle ID/net weight, 1000 cargo ID/cargo name, 1000

weighing records

- Weighing data save protection in case of power off

- Input character with keyboard

- Recall vehicle ID and cargo name by shortcut key

Parameters:

|

|

|

Digital

load cell connection

|

|

Load cell

connection distance

|

|

|

|

|

Max. load

cell connection

|

|

|

|

|

|

|

|

RS232C serial

communication,

Scoreboard at 20mA current loop

Parallel printer |

|