|

|

|

|

|

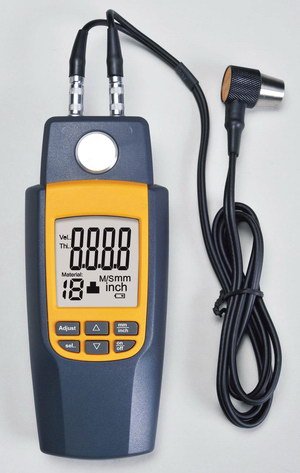

SR1810 |

SR1811 |

SR1812,SR1812C |

SR1816,SR1816C |

|

¡¡ |

¡¡ |

¡¡ |

¡¡ |

|

Specification |

Model |

SR1810 |

SR1811 |

SR1812 |

SR1812C |

SR1816, SR1816C |

|

Measuring range |

Metric Imperial |

1.5-200mm,0.06-8inch |

1.2-225mm,0.05-9inch |

1.0~200mm (45# steel) |

|

Operating principle |

Ultrasonic |

|

Materials measured |

Only 11types of materials, including Steel, Cast iron,

Aluminum, Red copper, Basra, Zinc, Quartz glass,

Polyethylene, PVC, Gray cast iron, Nodular cast iron. |

Any hard materials, including Steel, Cast iron, Aluminum,

Red copper, Brass, Zinc, Quartz glass, Polyethylene, PVC,

Gray cast iron, Nodular cast iron and other materials. |

|

Sound velocity |

-- |

500-9000m/s |

|

Lower limit steel pipes |

15x2.0mm, 20x3.0mm determined by the transducer |

|

Calibration block |

included |

|

Resolution |

0.1mm |

0.01mm |

0.1mm

(SR1816C 0.01mm) |

|

Accuracy |

¡À(0.5%n+0.2) |

¡À(0.5%n+0.1) |

|

RS-232C interface |

-- |

-- |

With RS-232C |

|

Power supply |

4x1.5VAA (UM-3) battery |

4x1.5VAAA (UM-4) battery |

|

Battery indicator |

low battery indicator |

|

Operating conditions |

Temperature: 0~40ºC; Humidity: 10~90%RH |

0-+45ºC(32¡ãF-104¡ãF),¡Ü90%RH |

|

Dimensions |

160x68x32mm |

120x62x30mm |

135x65x27mm (5.3x2.6x1.1 inch) |

|

Weight (Not including battery) |

208g |

164g |

120g |

|

Standard delivery |

Main unit |

1 |

1 |

|

5M ¦µ 8 transducer |

1 |

-- |

|

Couplant |

1 |

-- |

|

Test block |

-- |

1 |

|

Ultrasonic sensor |

-- |

1 |

|

Instruction manual |

1 |

1 |

|

Carrying case |

1 |

1 |

|

Optional Accessories |

6M ¦µ 6MM thin Material probe |

Measuring range (steel): 1.0~50.0mm

Operating temperature: -10~+60¡ãC |

-- |

|

5M ¦µ 12 high temperature probe |

Measuring range (steel): 1.2~225.0mm (normal temperature)

Measuring range (steel): 4.0~100.0mm (high temperature)

Operating temperature: -10~+300¡ãC |

-- |

|

RS-232C Cable & software, USB Cable & software, Bluetooth

data output |

Available only for SR1812 & SR1812C |

RS-232C Cable & software, USB Cable & software, Bluetooth

data output

¡¡ |

Please be noted:

SR Series 1-200 mm is only for 45# steel. For other materials, its

measurement thickness depends on the material hardness. For PVC, it

should be up to 20 mm.

Ultrasonic thickness meter can be used to test thickness of HARD

rubber, but can't be used to test thickness of SOFT rubber, as soft

rubber absorb too much ultrasonic.

SR1812, SR1816 Resolution is 0.1mm, while SR1812C, SR1816C is 0.01mm. |

|

¡¡ |

¡¡ |

|

|

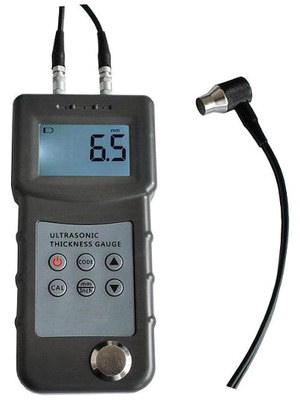

SR1041 Ultrasonic thickness meter

Key Features:

. Ulstranic measures thickness

. Various material

(metal/glass/plastics/pottery

and other materials) optional

. Ultrasonic velocity adjustable

. Measuring velocity function

. Thickness unit mm/inch convertible

. Coupling indication

. Build in a metal piece for calibration

. Low battery voltage indication.

. Auto power off

SPECIFICATIONS

.According to European union¡¯s CE safety norms

.Ultrasonic frequency: 5MHz

.Digital display: 4 digitals.

.Measuring range: 1.2mm~225mm(steel)

.Pipe measures: minimum dia. 20*3mm(steel)

.Velocity range: 1000~9999 meter/second

.Resolution: 0.1 mm.

.Accuracy: ¡À(1%H+0.1mm)

.Response time: 0.5 S

.Operating temperature: 0~40 ¡ãC

.Operating humidity: 10 to 90%RH

Accessories include:

Free ultrasonic sensor included

Free 1.5V x3AAA batteries

Free protective carrying case

Free Wrist Strap/String

User's Manual |

|

¡¡ |

¡¡ |

|

|

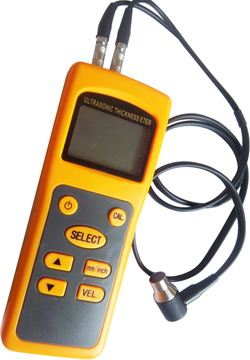

SR1650 Ultrasonic Thickness Gauge

Application:

Used for measuring thickness and corrosion of pressure vessels,

chemical equipment, boilers, oil storage tanks, etc. in industries

of petroleum, shipbuilding, power station, and machine

manufacturing.

Materials measured: only 11 types of materials, including steel,

cast iron, aluminum, red copper, brass, zinc, quartz glass,

polyethylene, PVC, gray cast iron, nodular cast iron

Feature:

High resolution measurement

Probe automatic zero calibration for system error correction

Capture the value of the minimum thickness.

Status indicator of the coupling and low battery.

Auto sleep and auto power off function to conserve battery life.

Humanized shape design, compact and portable, Can be used in harsh

environment.

Specifications:

1)Display: 4.5 digits LCD with EL backlight.

2)Operating principle: ULTRASONIC

3)Measuring range (metric/imperial): 1.0-200mm, 0.05-8inch (in

Steel).

4)Resolution: 0.1mm;

5)Accuracy: ¡À(0.5%H+0.1)mm, depends on materials and conditions

6)Units: Metric/Imperial unit selectable.

7)Power supply:4x1.5 AAA size (UM-4) battery 1

8)Battery indicator: low battery indicator

9)Operating conditions: 0-+45¡ãC(32ºF-104ºF), ¡Ü90%RH

10)Dimensions: Main Unit 140mm¡Á60mm¡Á22mm

11)Gloss Weight :1KG

12)Standard Delivery: Main Unit, 8mm Probe, Coupling Oil, User Manual

,Carrying Case

|

|

¡¡ |

¡¡ |

|

|

SR1670 Ultrasonic Thickness Gauge

Application:

Used for measuring thickness and corrosion of pressure vessels,

chemical equipment, boilers, oil storage tanks, etc. in industries

of petroleum, shipbuilding, power station, and machine

manufacturing.

Materials measured: any hard materials, including

steel, cast iron, aluminum, red copper, brass, zinc, quartz glass,

polyethylene, PVC, gray cast iron, nodular cast iron and other

ultrasonic wave well-conductive materials.

Feature:

High resolution measurement

Probe automatic zero calibration for system error correction

Two-Point calibration function. Sound-Velocity-Calibration function

According to the known thickness measurement Sound-Velocity.

Capture the value of the minimum thickness.

Status indicator of the coupling and low battery.

Auto sleep and auto power off function to conserve battery life.

Humanized shape design, compact and portable, Can be used in harsh

environment.

Specifications:

1)Display: 4.5 digits LCD with EL backlight.

2)Operating principle: ULTRASONIC

3)Measuring range (metric/imperial): 1.0-280mm, 0.05-11.0inch (in

Steel).

4)Sound Velocity Range: (500~9000) m/s.

5)Resolution: 0.1mm;

6)Accuracy: ¡À(0.5%H+0.1)mm, depends on materials and conditions

7)Units: Metric/Imperial unit selectable.

8)Power supply:4x1.5 AAA size (UM-4) battery 1

9)Battery indicator: low battery indicator

10)Operating conditions: 0-+45¡ãC(32ºF-104ºF), ¡Ü90%RH

11)Dimensions: Main Unit 140mm¡Á60mm¡Á22mm

12)Gloss Weight :1KG

13)Standard Delivery: Main Unit, 8mm Probe, Coupling Oil, User Manual

,Carrying Case

|

|

¡¡ |

¡¡ |

|

¡¡ |

¡¡ |

|

|

SR1812B Ultrasonic thickness meter

Measuring mode: Ultrasonic

Measurable materials: Thickness of any hard material, such as steel,

cast steel, aluminum, red copper, brass, zinc, silica glass,

polyethylene, PVC (polyvinyl chloride), gray cast iron, spheroidal

graphite cast iron, ceramic, plastic and any other good conductor of

ultrasonic

Specification:

Display: 4 digits, 16 mm LCD

Range: 1.0~200mm (45# steel)

Resolution: 0.1 mm/0.001inch

Accuracy: ¡À (0.5%+0.1)

Sound velocity: 500~9000 m/s

Power supply: 4x 1.5v AAA (UM-4) battery

Operating condition: Temp. 0~50¡ãC Humidity: < 80%

Size: 165x58x33mm

Weight: 120g (not including batteries)

Features:

* Used the exclusive Micro-computer LSI circuit and crystal time

base to offer high accuracy measurement.

* With high power of emission and broad band of receiving

sensitivity, the gauge can match probes of different

frequencies. That makes it easy to measure the rough surface, even

cast iron. It is widely used in almost all kinds of industries.

* Applicable to measure the thickness of many materials, e. g.

Steel, Cast iron, Aluminum, Red copper, Brass, Zinc, Quartz glass,

Polyethylene, PVC, Gray cast iron, Nodular cast iron.

* Automatic power off to conserve power.

Application: Thickness measurement and corrosion measurement

of petroleum, shipbuilding, power station, machine-building and

pressure vessel, chemical equipment boiler, oil tank, etc. |

|

¡¡ |

¡¡ |

|

|

SR1850 Ultrasonic Thickness Gauge

Features

Auto Calibration to assure the accuracy

Auto linear compensation: this advanced

software program enhances the precision by correcting the non-linear

accuracy of transducer

Use "up" and "down" keys to make a quick

adjustment for the sound velocity/thickness and a quick recall to

the stored data

Coupling status indication: Observing

the coupling icon to learn if the coupling is accomplished or not

10 thickness measurement storage and

recall function available, which facilitated the height work or

working in wild area

Sound velocity measurement: with a given

thickness by a sample hardware to measure the sound velocity, which

avoid the further conversion or consultation of the table

12 sound velocity for different material

which also adjustable

Low battery indication

Auto power off mode designed to conserve

battery life

More than 10000 times long life keys

The unit has a special memory that

retains all of its setting even when the power is off

Specification

LCD Digital display: 4 digits

Minimum display unit: 0.1 mm

Working frequency: 5 MHz

Measurement Range: 1.2 ~ 225.0 mm

(Steel)

Minimum limit for Tubes measurement:

¦µ20mm x 3mm (Steel)

Accuracy: ¡À (1% H + 0.1 mm) (H

denotes the measured thickness)

Sound Velocity Range: 1000 ~ 9999 m/s

Measuring Sound Velocity with a given

thickness

Measuring Range: 1000 ~ 9999 m/s

When the given thickness over 20mm, the

accuracy is ¡À1%; when the given thickness less than 20mm, the

accuracy is ¡À5%

Operating Temperature: 0 ~ 40 ¡ãC (32 ~

104 ¡ãF)

Power supply: 3 x 1.5 AAA Alkaline

Batteries (Included)

Operation Current:

Normal Operation Current ¡Ü 50 mA

With Backlight turn on current ¡Ü 120 mA

Stand-by Current: ¡Ü 20 ¦ÌA

Item Dimensions: approx. 72 (L) x 146

(W) x 29 (H) mm (2.83 x 5.75 x 1.14 inch)

Item Weight: approx. 202 g (7.12 oz)

(Batteries and probe included) |

|

¡¡ |

¡¡ |