|

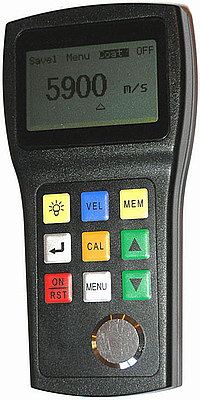

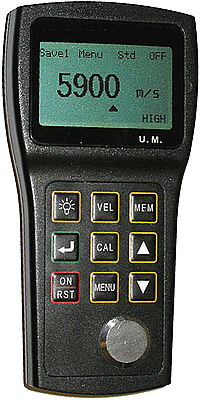

This gauge is a simple to use, high accuracy, hand-held Ultrasonic

Thickness Gauge with the ability to measure through paint and

coatings and even to eliminate the thickness of the paint or

coating. Through-Coating Thickness Measuring Capability

- You can now test painted tanks, pipes, etc.,

without having to remove the paint or make corrections for the paint

thickness.

Ideal for measuring the effects of corrosion or erosion on tanks,

pipes or any structure where access is limited to one side.

Operating principle:

Standard mode: P-E (pulse-echo) method with dual-element probes

Coating

mode: E-E (echo-echo) method with dual-element probes

|

| |

|

|

|

|

SR1911D

Thru-Paint

(Through coating, Through paint)

ultrasonic thickness gauge

Interfaces:

Serial

RS 232C port in combination with a communicative cable;

Data

transfer parameters: 8 bits, 1 stop bit, 9600 baud, no parity.

Standard package:

SR8911D

thickness gauge, Standard probe (PT-08)

Carrying case, Two 1.5V AA alkaline batteries

Couplant, Operating manual

Optional accessories:

Attachable rubber case

Numerous special probes on request

Couplants and high-temperature couplant

4-step/6-step block for calibration

Data

transmission cable

Application software |

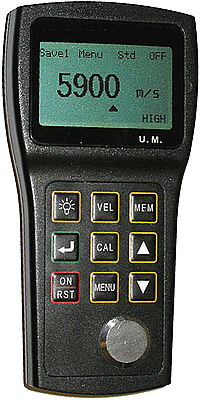

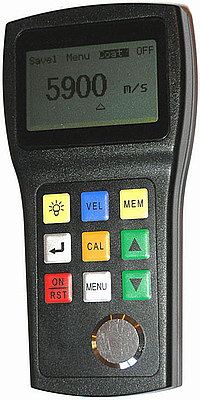

SR1912D

Thru-Paint (Through

coating, Through paint)

ultrasonic thickness gauge

Interfaces:

Serial

RS 232C port in combination with a communicative cable;

Data

transfer parameters: 8 bits, 1 stop bit, 9600 baud, no parity.

Standard package:

SR8912D

thickness gauge, Standard probe (PT-08)

Carrying case, Two 1.5V AA alkaline batteries

Couplant, Operating manual

Optional accessories:

Attachable rubber case

Numerous special probes on request

Couplants and high-temperature couplant

4-step/6-step block for calibration

Data

transmission cable

Application software |

|

|

Specification |

Model |

SR1911D |

SR1912D |

|

Measuring range |

Metric Imperial |

0.8mm to 300mm; 0.031in to 11.81in in standard mode

3.0mm to 18.0mm; 0.118in to 0.709in in through coating

mode

Depending on probe, material and surface condition |

|

Operating principle |

Ultrasonic |

|

Digital resolution |

0.001in or 0.1mm (less than SR1912D) |

H<4in

: 0.001in /0.01in or 0.01mm/0.1mm;

H≥4in : 0.01in or 0.1mm |

|

Units |

Selectable: inch or mm |

|

Display |

128*64 dot-matrix LCD screen (1.65in*2.24in; 42mm*57mm)

EL backlight and switchable contract ratio |

|

Measurement update rate |

4 Hz in standard measurement mode

25 Hz in MIN capture mode |

|

Material velocity range |

1000 to 9999 m/s; 0.039 to 0.394 inch/µs |

|

Power supply |

Two 1.5V AA alkaline batteries |

|

Warning with low battery voltage |

√ |

|

Auto shut-off |

After 5 minutes of non-use |

|

Probe zero adjustment |

Selectable: 1-point calibration: normal measurement

2-point calibration: curve surface

measurement or other special application with a high

precision |

|

V-path correction |

Automatic |

|

Dimensions |

149mm*73mm*32mm (H*W*D) |

|

Whole weight |

200g; 7oz (including batteries) |

|

Packing |

1PCS/CTN, CTN SIZE: 28*24*11, G.W.: 1.5KGS |

|

Display contents |

thickness value, coupling state, power state, CAL

calibration state, sound velocity |

|

Data logger capacity |

Up to 500 readings can be divided into a maximum of 5

files (user-selectable) |

|

Measuring error |

Up to 1in: ±0.002in or ±0.1mm

Above 1in: ± 1%H

H is the height of the testing object |

Up to 1in: ±0.002in or ±0.05mm

Above 1in: ±0.5%H

H is the height of the testing object |

|

Repeatability |

±0.001in or ±0.1mm |

±0.001in or ±0.025mm |

|

Application software |

UMVIEW |

|

Interfaces |

RS232 |

|

| |

|

.jpg)

★Color

320*240 Pixels Display

★A-Scan

Snapshot

★Echo-Echo

Mode(Thru Paint&Coatings)

★Stores

100000 Readings

★Gain:Low,Medium

or High for varying test conditions |

SR1914 Ultrasonic Thickness Gauge

Main functions of SR1914

The only product using

clear bright color OLED in the same product class.

Contrast:10000: 1 40 times than TFT color LCD screen

Resolution320*240,9 times than the same product class

Faster measurement update rate

Selectable 4Hz, 8Hz, 16Hz,4Hz for

ordinary use,higher update rate can be chosed when need a quick

scan.

The innovative A scanning snapshot function

Marks the economical thickness gauge into digital age.

SR1914 first provides A snapshot

scanning waveform display function in the same product

class.Ultrasonic is no longer an abstract concepts.Users can see

directly on the screen of ultrasonic signal,to verify the thickness

reading is correct, analyze the cause of the problem and help the

user to find the solution to the problem.

Industry's first economical digital thickness gauge

The zero measurement technology, high resolution, A scanning

snapshot function is based on full digital technology.

The only real 0.01 mm resolution of

ultrasonicthickness meter in the same product class.

Ultrasonic thickness gauge display resolution is

usually 0.01 mm, but it's hard for the real resolution up to 0.01

mm.Ordinary Timing counter within the thickness gauge is generally

below 30 MHZ,With the breakthrough full digital technology and

special algorithm, The true resolution of SR1914 can reach 0.01 mm,

Lots of experiments prove that it's easy for SR1914 to distinguish

that thickness is only 0.01mm of two blocks.

Adopted the zero measurement technology

Based on full digital technology,with the zero

measurement technology,the measured value will not be affected by

echo intensity,material attenuation coefficient,the gain and the

height of the gate,so the result was of high stability and

reliability.

More practical function

Alarm,DIFF/RR%,Min/max Capture

|

SR1914 Series Technical Specifications

|

Instrument Specifications |

|

Display Type |

2.4" color OLED, 320 * 240 pixels, contrast 10,000:1 |

|

Operating Principle |

Pulse echo with dual element transducers |

|

Measuring Range |

0.60mm to 508mm(0.025" to 20.00"), depending on material,

probe and surface condition |

|

Measuring Resolution |

Selectable 0.01mm, 0.1mm (selectable 0.001",

0.01") |

|

Units |

Inch or Millimeter |

|

Gain |

Low, Medium or High for varying test conditions |

|

Display Mode |

Normal, Minimum / Maximum capture, DIFF/RR% |

|

V-Path Correction |

Automatic |

|

Update Rate |

Selectable 4Hz, 8Hz, 16Hz |

|

Material Velocity Range |

500 to 9999m/s (0.0197 to 0.3937in/us) |

|

Languages |

Selectable Chinese, English, Japanese |

|

Alarm Settings |

Minimum and Maximum alarms. Range of 0.25 mm to 508 mm

(0.010" to 20.00").Dynamic waveform color change on alarm |

|

Power Requirements |

2 AA size batteries |

|

Operating Time |

Approximately 40 hours |

|

Instrument Shut-off |

Selectable ALWAYS ON or AUTO OFF after 5, 10, 20 minutes of

inactivity |

|

Operating Temperature |

-10°C to +50°C (+10°F to +120°F) |

|

Size |

153mm * 76mm * 37mm(H * W * D) |

|

Weight |

280g including batteries |

SR1914 Standard Configuration

|

SR1914 thickness gauge |

1 |

Standard Probe |

1 |

|

Carrying Case |

1 |

Couplant |

1 |

|

Operating Mannual |

1 |

1.5AA Alkaline batteries |

2 |

|

SR1914 Series Probe/Transducer Specifications |

|

Model |

PT08 |

TC510 |

PT12 |

ZT12 |

PT06 |

PT04 |

GT12 |

|

Type |

SR1914 Standard |

SR1914D/SR1914DL Standard |

Standard |

Cast iron |

Small tube |

Fingertip |

High-Temperature |

|

Frequency |

5MHz |

5MHz |

5MHz |

2MHz |

7.5MHz |

10MHz |

5MHz |

|

Contact Diameter |

11mm |

13.5mm |

13.5mm |

17mm |

8mm |

6mm |

15mm |

|

Measurement Range |

0.8 to

100.0mm |

1.2 to

200.0mm |

1.0 to 200.0mm |

4.0 to

508.0mm |

0.8 to

30.0mm |

0.7 to 12.0mm |

4.0 to

80.0mm |

|

Temperature Range |

-10 to 70°C |

-10 to

70°C |

-10 to 70°C |

-10 to 70°C |

-10 to

70°C |

-10 to 70°C |

-20 to 300°C |

|

| |

|

.jpg)

★Color

320*240 Pixels Display

★A-Scan

Snapshot

★Echo-Echo

Mode(Thru Paint&Coatings)

★Stores

100000 Readings

★Gain:Low,Medium

or High for varying test conditions |

SR1914D Ultrasonic Thickness Gauge

Main functions of

SR1914D

The only product using

clear bright color OLED in the same product class.

Contrast:10000: 1 40 times than TFT color LCD screen

Resolution320*240,9 times than the same product class

Faster measurement update rate

Selectable 4Hz,8Hz,16Hz, 4Hz for

ordinary use,higher update rate can be chosed when need a quick

scan.

The innovative A scanning snapshot function

Marks the economical thickness gauge into digital age.

SR1914D first provides A snapshot

scanning waveform display function in the same product

class.Ultrasonic is no longer an abstract concepts.Users can see

directly on the screen of ultrasonic signal,to verify the thickness

reading is correct, analyze the cause of the problem and help the

user to find the solution to the problem.

Industry's first economical digital thickness gauge

The zero measurement technology,high resolution, A

scanning snapshot function is based on ful digital technology.

The SR1914D now offers

Through-Coating Thickness Measuring Capability

-You can now test painted tanks, pipes, etc., without needing to

remove the paint or make corrections for the paint thickness. 1.no

need of zero calibration 2.Measured value is not affected by

coupling probe pressure, layer thickness and the influence of the

surface dirt stains

The only real 0.01 mm resolution of

ultrasonicthickness meter in the same product class.

Ultrasonic thickness gauge display resolution is

usually 0.01 mm, but it's hard for the real resolution up to 0.01

mm.Ordinary Timing counter within the thickness gauge is generally

below 30 MHZ,With the breakthrough full digital technology and

special algorithm, The true resolution of SR1914 can reach 0.01 mm,

Lots of experiments prove that it's easy for SR1914 to distinguish

that thickness is only 0.01mm of two blocks.

Adopted the zero measurement technology

Based on full digital technology,with the zero

measurement technology,the measured value will not be affected by

echo intensity,material attenuation coefficient,the gain and the

height of the gate,so the result has high stability and reliability.

More practical function

Alarm,DIFF/RR%,Min/max Capture

|

|

SR1914 Series Technical Specifications

|

Instrument Specifications |

|

Display Type |

2.4" color OLED, 320 * 240 pixels, contrast 10,000:1 |

|

Operating Principle |

Pulse echo with dual element transducers |

|

Measuring Range |

0.60mm to 508mm(0.025" to 20.00"), depending on material,

probe and surface condition |

|

Measuring Resolution |

Selectable 0.01mm, 0.1mm (selectable 0.001",

0.01") |

|

Units |

Inch or Millimeter |

|

Gain |

Low, Medium or High for varying test conditions |

|

Display Mode |

Normal, Minimum / Maximum capture, DIFF/RR% |

|

V-Path Correction |

Automatic |

|

Update Rate |

Selectable 4Hz, 8Hz, 16Hz |

|

Material Velocity Range |

500 to 9999m/s (0.0197 to 0.3937in/us) |

|

Languages |

Selectable Chinese, English, Japanese |

|

Alarm Settings |

Minimum and Maximum alarms. Range of 0.25 mm to 508 mm

(0.010" to 20.00").Dynamic waveform color change on alarm |

|

Power Requirements |

2 AA size batteries |

|

Operating Time |

Approximately 40 hours |

|

Instrument Shut-off |

Selectable ALWAYS ON or AUTO OFF after 5, 10, 20 minutes of

inactivity |

|

Operating Temperature |

-10°C to +50°C (+10°F to +120°F) |

|

Size |

153mm * 76mm * 37mm(H * W * D) |

|

Weight |

280g including batteries |

SR1914D Standard Configuration

|

SR1914D thickness gauge unit |

1 |

Standard Probe |

1 |

|

Carrying Case |

1 |

Couplant |

1 |

|

Operating Mannual |

1 |

1.5V AA Alkaline batteries |

2 |

|

SR1914 Series Probe/Transducer Specifications |

|

Model |

PT08 |

TC510 |

PT12 |

ZT12 |

PT06 |

PT04 |

GT12 |

|

Type |

SR1914 Standard |

SR1914D/SR1914DL Standard |

Standard |

Cast iron |

Small tube |

Fingertip |

High-Temperature |

|

Frequency |

5MHz |

5MHz |

5MHz |

2MHz |

7.5MHz |

10MHz |

5MHz |

|

Contact Diameter |

11mm |

13.5mm |

13.5mm |

17mm |

8mm |

6mm |

15mm |

|

Measurement Range |

0.8 to

100.0mm |

1.2 to

200.0mm |

1.0 to 200.0mm |

4.0 to

508.0mm |

0.8 to

30.0mm |

0.7 to 12.0mm |

4.0 to

80.0mm |

|

Temperature Range |

-10 to 70°C |

-10 to

70°C |

-10 to 70°C |

-10 to 70°C |

-10 to

70°C |

-10 to 70°C |

-20 to 300°C |

|

| |

|

.jpg)

★Color

320*240 Pixels Display

★A-Scan

Snapshot

★Echo-Echo

Mode(Thru Paint&Coatings)

★Stores

100000 Readings

★Gain:Low,Medium

or High for varying test conditions |

SR1914DL Ultrasonic Thickness Gauge

Main functions of SR1914DL

The only product using

clear bright color OLED in the same product class.

Contrast:10000: 1 40 times than TFT color LCD screen

Resolution320*240,9 times than the same product class

Faster measurement update rate

Selectable 4Hz,8Hz,16Hz, 4Hz for

ordinary use,higher update rate can be chosed when need a quick

scan.

The innovative A scanning snapshot function

Marks the economical thickness gauge into digital age.

SR1914DL first provides A snapshot

scanning waveform display function in the same product

class.Ultrasonic is no longer an abstract concepts.Users can see

directly on the screen of ultrasonic signal,to verify the thickness

reading is correct, analyze the cause of the problem and help the

user to find the solution to the problem.

Industry's first economical digital thickness gauge

The zero measurement technology, high resolution, A scanning

snapshot function is based on full digital technology.

The SR1914DL now offers

Through-Coating Thickness Measuring Capability.

-You can now test painted tanks, pipes, etc., without needing to

remove the paint or make corrections for the paint thickness. 1.no

need of zero calibration 2.Measured value is not affected by

coupling probe pressure, layer thickness and the influence of the

surface dirt stains 3.zero drift

More memory, more convenient storage

capability.

Store 100000 thickness value, is 20 to 200 times of

class products;domestic first grid type of storage files display 15

thickness value per screen,According to its position in the grid,

making it easy for users to browse the thickness data ,USB 2.0 (Full

Speed) ,Powerful DataView data statistics and management software

The only real 0.01 mm resolution of

ultrasonicthickness meter in the same product class.

Ultrasonic thickness gauge display resolution is

usually 0.01 mm, but it's hard for the real resolution up to 0.01

mm.Ordinary Timing counter within the thickness gauge is generally

below 30 MHZ,With the breakthrough full digital technology and

special algorithm, The true resolution of SR1914 can reach 0.01 mm,

Lots of experiments prove that it's easy for SR1914 to distinguish

that thickness is only 0.01mm of two blocks.

Adopted the zero measurement technology

Based on full digital technology,with the zero

measurement technology,the measured value will not be affected by

echo intensity,material attenuation coefficient,the gain and the

height of the gate,so the result has high stability and reliability.

More practical function

Alarm,DIFF/RR%,Min/max Capture

|

|

SR1914

Series Technical Specifications

|

Instrument Specifications |

|

Display Type |

2.4" color OLED, 320 * 240 pixels, contrast 10,000:1 |

|

Operating Principle |

Pulse echo with dual element transducers |

|

Measuring Range |

0.60mm to 508mm(0.025" to 20.00"), depending on material,

probe and surface condition |

|

Measuring Resolution |

Selectable 0.01mm, 0.1mm (selectable 0.001",

0.01") |

|

Units |

Inch or Millimeter |

|

Gain |

Low, Medium or High for varying test conditions |

|

Display Mode |

Normal, Minimum / Maximum capture, DIFF/RR% |

|

V-Path Correction |

Automatic |

|

Update Rate |

Selectable 4Hz, 8Hz, 16Hz |

|

Material Velocity Range |

500 to 9999m/s (0.0197 to 0.3937in/us) |

|

Languages |

Selectable Chinese, English, Japanese |

|

Alarm Settings |

Minimum and Maximum alarms. Range of 0.25 mm to 508 mm

(0.010" to 20.00").Dynamic waveform color change on alarm |

|

Power Requirements |

2 AA size batteries |

|

Operating Time |

Approximately 40 hours |

|

Instrument Shut-off |

Selectable ALWAYS ON or AUTO OFF after 5, 10, 20 minutes of

inactivity |

|

Operating Temperature |

-10°C to +50°C (+10°F to +120°F) |

|

Size |

153mm * 76mm * 37mm(H * W * D) |

|

Weight |

280g including batteries |

|

Data Logger Option Features |

|

Capacity |

400 files, 100,000 readings |

|

File Structure |

Grid file |

|

Rows * Columns |

21 * 12 |

|

Communication Port |

USB 2.0 (Full Speed ) port |

|

Software |

DataView PC software |

SR1914DL

Standard Configuration

|

SR1914DL thickness gauge unit |

1 |

Stand Probe |

1 |

|

Carrying Case |

1 |

Couplant |

1 |

|

Operating Mannual |

1 |

1.5AA Alkaline Batteries |

2 |

|

SR1914DL Series Probe/Transducer Specifications |

|

Model |

PT08 |

TC510 |

PT12 |

ZT12 |

PT06 |

PT04 |

GT12 |

|

Type |

SR1914 Standard |

SR1914D/SR1914DL Standard |

Standard |

Cast iron |

Small tube |

Fingertip |

High-Temperature |

|

Frequency |

5MHz |

5MHz |

5MHz |

2MHz |

7.5MHz |

10MHz |

5MHz |

|

Contact Diameter |

11mm |

13.5mm |

13.5mm |

17mm |

8mm |

6mm |

15mm |

|

Measurement Range |

0.8 to

100.0mm |

1.2 to

200.0mm |

1.0 to 200.0mm |

4.0 to

508.0mm |

0.8 to

30.0mm |

0.7 to 12.0mm |

4.0 to

80.0mm |

|

Temperature Range |

-10 to 70°C |

-10 to

70°C |

-10 to 70°C |

-10 to 70°C |

-10 to

70°C |

-10 to 70°C |

-20 to 300°C |

|

| |

|

.JPG)

★Color

OLED 320*240 Pixels Display

★Live

Simultaneous Color A-Scan and Thickness Display

★Control

of Gain, Blanking, Gate, Range, Delay, RF and Rectify Modes

★Time-based

B-Scan Display

★Echo-Echo

Mode(Thru Paint & Coatings)

★Stores

100,000 Readings and 1000 waveform

If the ordinary thickness gauges are incompetent in

the rough applications. Please turn to our SR1915, which will

maximize measurement performance for challenging applications and

provide you with the cost-effective measurement solutions.

SR1915 Operation Principle

The ordinary ultrasonic thickness gauge with the

principle pulse/echo method could do the test by the following two

conditions.

1. The first underside echo must be higher than the

gate. (The height of the electrical level of the gate is

unadjustable)

2. No other noise waves before the first underside

echo are higher than the gate. (Otherwise, we will get the

thickness where the noise wave are produced)

For some conditions, the above situations could not

be satisfied,for example, the highly corrosive near surface,

coarse-grain materials (e.g. cast iron),aluminum, small diameter

pipes, super thin sheet, super thick plate, rough surface,

nonuniform inner structure, defect contained workpiece, lamination

and so on which could not be tested by the ordinary gauges.

SR1915 will solve the above problems easily:

1. Make the first underside wave higher than the gate

by adjusting the gain and height of the gate.

2. Invalidate noise waves before the first underside

wave by the function of blanking. |

SR1915 Ultrasonic Thickness Gauge

MAIN FEATURES OF SR1915

Live Color A-Scan

User could directly see the color waveform of the

ultrasonic sound (or A-scan) on the screen, which is quite important

for the occasions that we need to check the correctness of the

testing results. Many cases will cause wrong testing results or even

no readings. We could find the causes easily through the A-scan.

Adjust the three parameters of GAIN, BLACKING, GATE, and then we

will get the right readings.The uses for waveform: testing the

correctness of thickness readings, finding out the causes of

impacting the testing, and adjusting the parameters to solve the problems.

GAIN ADJUSTMENT

Adjust the amplification factor of echo signal,

increasing and reducing by 1 dB by hand. It is quite effective for

acoustic attenuation materials (e.g. cast iron).

BLANKING

Invalidate the waves within the red blanking strip,

and omit the useless noise waves that impact the measuring like the

waves caused by the rough surface or nonuniform inner structure.

GATE

The gauge will get the reading only when the wave is

omit the front noise waves by blanking higher than the gate. So the

adjustable height of gate is very important, especially for the

applications of low echo signals (e.g. super thin sheet, super thick

plate)

RED ARROW

The first intersection point between the waveform and

gate is pointed by a red arrow, which can help judging whether the

thickness value is correct (the red arrow should point the front of

the first bottom echo if correctly tested).

RANGE

Adjust the wave scope on the screen, and they are

visually compressed or spreaded. Without the correct wave range, the

wave may be out of the screen, but the right reading will still

show.

DELAY

Tthe initial position of the wave on the screen, the

wave will be moved visually. Without the correct wave range, the

wave may be out of the screen, but the right reading will still

show.The functions of RANGE and DELAY could magnify any section of

the wave showing on the screen.

Live ColorB-Scan

SR1915 series thickness gauge has time-base B-scan

function. Move the probe along the workpiece surface, then the

cross-sectional profile of the workpiece display, use for observe

the underside contour of the workpiece.

When remove the probe from workpiece, it could be automatically

capture a minimum value of the B-scan image, and indicate the

position of the minimum by a red triangle. You can see any point

thickness value of the B-scan image by moving the pointer.

RecitifIcation Modes:four modes selective

RF: describe the whole echo waveform;

Half+: Show the Half -Wave positive without the Half-

Wave negative;

Half-: Show the Half-Wave negative without the

Half-Wave Negative;

FULL:show both the Half-Wave Positive and upturned

Half-Wave Negative.

More Practical Functions

DIFFERENCE/RATE DIFF/RR%: This interface displays

the currently measured and a nominal thickness input by user, the

difference between the currently measured thickness and the nominal

thickness and the ratio between the difference and the nominal

thickness. Before using this mode, presetting the nominal thickness

is needed.

Max./Min.

Capture: On this mode, the current

thickness, minimum thickness and the maximum thickness will be shown

on the screen at the same time. You could drag the probe along the

surface of the work, and the minimum and maximum will be shown

automatically on the screen.

Alarm Mode: Dynamic

waveform color change on alarm

Update Rate: Update the rate of measurement result.

Optional 4Hz, 8 Hz and 16Hz.

Multi-

Languages Available: English,Chinese,Japanese,etc. |

|

|

SR1915 Probe/Transducer Specifications |

|

Model |

PT08 |

TC510 |

PT12 |

ZT12 |

PT06 |

PT04 |

GT12 |

|

Type |

SR1915

Standard |

SR1915D/SR1915DL Standard |

Standard |

Cast iron |

Small tube |

Fingertip |

High-Temperature |

|

Frequency |

5MHz |

5MHz |

5MHz |

2MHz |

7.5MHz |

10MHz |

5MHz |

|

Contact Diameter |

11mm |

13.5mm |

13.5mm |

17mm |

8mm |

6mm |

15mm |

|

Measurement Range |

0.8 to

100.0mm |

1.2 to

200.0mm |

1.0 to 200.0mm |

4.0 to

508.0mm |

0.8 to

30.0mm |

0.7 to 12.0mm |

4.0 to

80.0mm |

|

Temperature Range |

-10 to 70°C |

-10 to

70°C |

-10 to 70°C |

-10 to 70°C |

-10 to

70°C |

-10 to 70°C |

-20 to 300°C |

|

Specifications

Pulse echo with dual element transducers

Measuring Range

0.5 to 508mm(0.02" to 20.00"),

depending on probe,material and surface condition

Unit and Display Resolution

mm-0.01,0.1

inch-0.001,0.01

Display Mode

Normal

A-Scan

B-Scan

Max./Min.Capture

DIFF/RR%

V- Path Correction

Automatic

Measuring Error

±0.05mm (25mm below)

±0.2% H (100mm above)

±0.5% H (100mm above)

H is the height of testing object

Repeatability

±0.05mm

Display

2.4" color OLED, 320 * 240 pixels

Measurement Update Rate

Selectable4Hz,8Hz,16Hz |

Velocity Range

500~9999m/s,0.0197~0.3937in/us

Operating Language

Chinese,English,Japanese(Selectable)

Power Supply

Two 1.5V AA batteries

Operating Time

Two 1.5V AA batteries,Approximately

36 hours.

Auto Shut-off

After 5,10,20 minutes of non-action period

Working Temperature

-10°C~+50°C,available

for as low as-20°C on request

Size

153mm*76mm*37mm (H*W*D)

Weight

280g including batteries

Standard Package

UM-5 thickness gauge unit

Standard Probe (PT-08)

Carrying Case

Two 1.5V AA batteries

Couplant

Operating Mannual

Accessories

Numerous special probes;step

calibration;

Couplant and Hight temperature Couplant |

|

| |

|

.JPG)

★Color

OLED 320*240 Pixels Display

★Live

Simultaneous Color A-Scan and Thickness Display

★Control

of Gain, Blanking, Gate, Range, Delay, RF and Rectify Modes

★Time-based

B-Scan Display

★Echo-Echo

Mode(Thru Paint & Coatings)

★Stores

100,000 Readings and 1000 waveform

SR1915D Operation Principle

If the ordinary thickness gauges are incompetent in

the rough applications. Please turn to our UM-5, which will maximize

measurement performance for challenging applications and provide you

with the cost-effective measurement solutions.

The ordinary ultrasonic thickness gauge with the

principle pulse/echo method could do the test by the following two

conditions.

1. The first underside echo must be higher than the gate. (The

height of the electrical level of the gate is unadjustable)

2. No other noise waves before the first underside echo are higher

than the gate. (Otherwise, we will get the thickness where the

noise wave are produced)

For some conditions, the above

situations could not be satisfied,for example, the highly corrosive

near surface, coarse-grain materials (e.g. cast iron),aluminum,

small diameter pipes, super thin sheet, super thick plate, rough

surface, nonuniform inner structure, defect contained workpiece,

lamination and so on which could not be tested by the ordinary

gauges.

SR1915D will solve the above problems easily:

1. Make the first underside wave higher than the gate by adjusting

the gain and height of the gate.

2. Invalidate noise waves before the first underside wave by the

function of blanking.

|

SR1915D Ultrasonic Thickness Gauge

MAIN FEATURES OF SR1915D

(Live Color A-Scan)

User could directly see the color waveform of the

ultrasonic sound (or A-scan) on the screen, which is quite important

for the occasions that we need to check the correctness of the

testing results. Many cases will cause wrong testing results or even

no readings. We could find the causes easily through the A-scan.

Adjust the three parameters of GAIN, BLACKING, GATE, and then we

will get the right readings.The uses for waveform: testing the

correctness of thickness readings, finding out the causes of

impacting the testing, and adjusting the parameters to solve the

problems.

GAIN

Adjust the amplification factor of echo signal,

increasing and reducing by 1 dB by hand. It is quite effective for

acoustic attenuation materials (e.g. cast iron).

BLANKING

Invalidate the waves within the red blanking strip,

and omit the useless noise waves that impact the measuring like the

waves caused by the rough surface or nonuniform inner structure.

GATE

The gauge will get the reading only when the wave

is omit the front noise waves by blanking higher than the gate.

So the adjustable height of gate is very important, especially for

the applications of low echo signals (e.g. super thin sheet, super

thick plate)

Red Arrow

The first intersection point between the waveform and

gate is pointed by a red arrow, which can help judging whether the

thickness value is correct (the red arrow should point the front of

the first bottom echo if correctly tested).

RANGE

Adjust the wave scope on the screen, and they are

visually compressed or spreaded. Without the correct wave range, the

wave may be out of the screen, but the right reading will still

show.

DELAY

the initial position of the wave on the screen, the

wave will be moved visually. Without the correct wave range, the

wave may be out of the screen, but the right reading will still

show.The functions of RANGE and DELAY could magnify any section of

the wave showing on the screen.

Live ColorB-Scan

UM-5 series thickness gauge has time-base B-scan

function. Move the probe along the workpiece surface, then the

cross-sectional profile of the workpiece display, use for observe

the underside contour of the workpiece.

When remove the probe from workpiece, it could be automatically

capture a minimum value of the B-scan image, and indicate the

position of the minimum by a red triangle. You can see any point

thickness value of the B-scan image by moving the pointer.

RecitifIcation modes:four modes selective

RF HALF+, HALF-, FULL.

RF: describe the whole echo waveform;

Half+: Show the Half -Wave positive without the Half- Wave negative;

Half-: Show the Half-Wave negative without the Half-Wave

Negative;

FULL: show both the Half-Wave Positive and upturned Half-Wave

Negative.

Through-Coating or Paint Thickness Measuring Capability,

SR1915Doffers Through-Coating or Paint

Thickness,Measuring Capability - You can now test painted tanks,

pipes, etc., without needing to remove the paint or make corrections

for the paint thickness:

1,Without need of zero calibration;

2,Hight stability,Measured value is not affected by coupling probe

pressure, layer thickness and the influence of the surface dirt

stains;

3,Zero drift.

More practical functions:

DIFFERENCE/RATE DIFF/RR%: this interface displays the

currently measured and a nominal thickness input by user, the

difference between the currently measured thickness and the nominal

thickness and the ratio between the difference and the nominal

thickness. Before using this mode, presetting the nominal thickness

is needed.

Max./Min. Capture: On this mode, the current

thickness, minimum thickness and the maximum thickness will be shown

on the screen at the same time. You could drag the probe along the

surface of the work, and the minimum and maximum will be shown

automatically on the screen.

Alarm Mode: Dynamic waveform color change on alarm

Update Rate: Update the rate of measurement result.

Optional 4Hz, 8 Hz and 16Hz.

Multi- Languages Available: Chinese,English,Japanes

etc. |

|

|

SR1915D Probe/Transducer Specifications |

|

Model |

PT08 |

TC510 |

PT12 |

ZT12 |

PT06 |

PT04 |

GT12 |

|

Type |

SR1915

Standard |

SR1915D/SR1915DL Standard |

Standard |

Cast iron |

Small tube |

Fingertip |

High-Temperature |

|

Frequency |

5MHz |

5MHz |

5MHz |

2MHz |

7.5MHz |

10MHz |

5MHz |

|

Contact Diameter |

11mm |

13.5mm |

13.5mm |

17mm |

8mm |

6mm |

15mm |

|

Measurement Range |

0.8 to

100.0mm |

1.2 to

200.0mm |

1.0 to 200.0mm |

4.0 to

508.0mm |

0.8 to

30.0mm |

0.7 to 12.0mm |

4.0 to

80.0mm |

|

Temperature Range |

-10 to 70°C |

-10 to

70°C |

-10 to 70°C |

-10 to 70°C |

-10 to

70°C |

-10 to 70°C |

-20 to 300°C |

|

Specifications

Pulse echo with dual element transducers

Measuring Range

0.5 to 508mm(0.02" to 20.00"),

depending on probe,material and surface condition

Unit and Display Resolution

mm-0.01,0.1

inch-0.001,0.01

Display Mode

Normal

A-Scan

B-Scan

Max./Min.Capture

DIFF/RR%

V- Path Correction

Automatic

Measuring Error

±0.05mm (25mm below)

±0.2% H (100mm above)

±0.5% H (100mm above)

H is the height of testing object

Repeatability

±0.05mm

Display

2.4" color OLED, 320 * 240 pixels

Measurement Update Rate

Selectable4Hz,8Hz,16Hz |

Velocity Range

500~9999m/s,0.0197~0.3937in/us

Operating Language

Chinese,English,Japanese(Selectable)

Power Supply

Two 1.5V AA batteries

Operating Time

Two 1.5V AA batteries,Approximately

36 hours.

Auto Shut-off

After 5,10,20 minutes of non-action period

Working Temperature

-10°C~+50°C,available

for as low as-20°C on request

Size

153mm*76mm*37mm (H*W*D)

Weight

280g including batteries

Standard Package

UM-5 thickness gauge unit

Standard Probe (PT-08)

Carrying Case

Two 1.5V AA batteries

Couplant

Operating Mannual

Accessories

Numerous special probes;step

calibration;

Couplant and Hight temperature Couplant |

|

| |

|

.JPG)

★Color

OLED 320*240 Pixels Display

★Live

Simultaneous Color A-Scan and Thickness Display

★Control

of Gain, Blanking, Gate, Range, Delay, RF and Rectify Modes

★Time-based

B-Scan Display

★Echo-Echo

Mode(Thru Paint & Coatings)

★Stores

100,000 Readings and 1000 waveform

SR1915DL Technical Specifications

If the ordinary thickness gauges are incompetent in the rough

applications. Please turn to our UM-5, which will maximize

measurement performance for challenging applications and provide you

with the cost-effective measurement solutions.

The ordinary ultrasonic thickness gauge with the

principle pulse/echo method could do the test by the following two

conditions.

1. The first underside echo must be higher than the gate. (The

height of the electrical level of the gate is unadjustable)

2. No other noise waves before the first underside echo are higher

than the gate. (Otherwise, we will get the thickness where the

noise wave are produced)

For some conditions, the above

situations could not be satisfied,for example, the highly corrosive

near surface, coarse-grain materials (e.g. cast iron),aluminum,

small diameter pipes, super thin sheet, super thick plate, rough

surface, nonuniform inner structure, defect contained workpiece,

lamination and so on which could not be tested by the ordinary

gauges.

SR1915DL will solve the above problems easily:

1. Make the first underside wave higher than the gate by adjusting

the gain and height of the gate。

2. Invalidate noise waves before the first underside wave by the

function of blanking.

|

SR1915DL Ultrasonic Thickness Gauge

MAIN FEATURES OF SR1915DL

(Live Color A-Scan)

User could directly see the color waveform of the

ultrasonic sound (or A-scan) on the screen, which is quite important

for the occasions that we need to check the correctness of the

testing results. Many cases will cause wrong testing results or even

no readings. We could find the causes easily through the A-scan.

Adjust the three parameters of GAIN, BLACKING, GATE, and then we

will get the right readings.The uses for waveform: testing the

correctness of thickness readings, finding out the causes of

impacting the testing, and adjusting the parameters to solve the

problems.

GAIN

Adjust the amplification factor of echo signal,

increasing and reducing by 1 dB by hand. It is quite effective for

acoustic attenuation materials (e.g. cast iron).

BLANKING

Invalidate the waves within the red blanking strip,

and omit the useless noise waves that impact the measuring like the

waves caused by the rough surface or nonuniform inner structure.

GATE

The gauge will get the reading only when the wave

is omit the front noise waves by blanking higher than the gate.

So the adjustable height of gate is very important, especially for

the applications of low echo signals (e.g. super thin sheet, super

thick plate)

Red Arrow

The first intersection point between the waveform and

gate is pointed by a red arrow, which can help judging whether the

thickness value is correct (the red arrow should point the front of

the first bottom echo if correctly tested).

RANGE

Adjust the wave scope on the screen, and they are

visually compressed or spreaded. Without the correct wave range, the

wave may be out of the screen, but the right reading will still

show.

DELAY

the initial position of the wave on the screen, the

wave will be moved visually. Without the correct wave range, the

wave may be out of the screen, but the right reading will still

show.The functions of RANGE and DELAY could magnify any section of

the wave showing on the screen.

Live ColorB-Scan

SR1915 series thickness gauge has time-base B-scan

function. Move the probe along the workpiece surface, then the

cross-sectional profile of the workpiece display, use for observe

the underside contour of the workpiece.

When remove the probe from workpiece, it could be

automatically capture a minimum value of the B-scan image, and

indicate the position of the minimum by a red triangle. You can see

any point thickness value of the B-scan image by moving the pointer.

DELAY

RecitifIcation modes:four modes selective

RF HALF+, HALF-, FULL .

RF: describe the whole echo waveform;

Half+: Show the Half -Wave positive without the

Half- Wave negative;

Half-: Show the Half-Wave negative without the Half-Wave

Negative;

FULL: show

both the Half-Wave Positive and upturned Half-Wave Negative.

More practical functions:

DIFFERENCE/RATE DIFF/RR%: this

interface displays the currently measured and a nominal thickness

input by user, the difference between the currently measured

thickness and the nominal thickness and the ratio between the

difference and the nominal thickness. Before using this mode,

presetting the nominal thickness is needed.

Max./Min. Capture: On

this mode, the current thickness, minimum thickness and the maximum

thickness will be shown on the screen at the same time. You could

drag the probe along the surface of the work, and the minimum and

maximum will be shown automatically on the screen.

Alarm Mode: Dynamic

waveform color change on alarm

Update Rate: Update

the rate of measurement result. Optional 4Hz, 8 Hz and 16Hz.

Multi- Languages Available: Chinese,English,Japanes

etc. |

|

SR1915DL Probe/Transducer Specifications |

|

Model |

PT08 |

TC510 |

PT12 |

ZT12 |

PT06 |

PT04 |

GT12 |

|

Type |

SR1915

Standard |

SR1915D/SR1915DL Standard |

Standard |

Cast iron |

Small tube |

Fingertip |

High-Temperature |

|

Frequency |

5MHz |

5MHz |

5MHz |

2MHz |

7.5MHz |

10MHz |

5MHz |

|

Contact Diameter |

11mm |

13.5mm |

13.5mm |

17mm |

8mm |

6mm |

15mm |

|

Measurement Range |

0.8 to

100.0mm |

1.2 to

200.0mm |

1.0 to 200.0mm |

4.0 to

508.0mm |

0.8 to

30.0mm |

0.7 to 12.0mm |

4.0 to

80.0mm |

|

Temperature Range |

-10 to 70°C |

-10 to

70°C |

-10 to 70°C |

-10 to 70°C |

-10 to

70°C |

-10 to 70°C |

-20 to 300°C |

|

Data Logger Option Features |

|

Capacity |

100,000 readings, 1000 waveforms,400 files |

|

File Structure |

Grid file |

|

Rows * Columns |

21 * 12 |

|

Communication Port |

USB 2.0 (Full Speed ) port |

|

Software |

DataView PC software |

|

Specifications

Pulse echo with dual element transducers

Measuring Range

0.5 to 508mm(0.02" to 20.00"),

depending on probe,material and surface condition

Unit and Display Resolution

mm-0.01,0.1

inch-0.001,0.01

Display Mode

Normal

A-Scan

B-Scan

Max./Min.Capture

DIFF/RR%

V- Path Correction

Automatic

Measuring Error

±0.05mm (25mm below)

±0.2% H (100mm above)

±0.5% H (100mm above)

H is the height of testing object

Repeatability

±0.05mm

Display

2.4" color OLED, 320 * 240 pixels

Measurement Update Rate

Selectable4Hz,8Hz,16Hz |

Velocity Range

500~9999m/s,0.0197~0.3937in/us

Operating Language

Chinese,English,Japanese(Selectable)

Power Supply

Two 1.5V AA batteries

Operating Time

Two 1.5V AA batteries,Approximately

36 hours.

Auto Shut-off

After 5,10,20 minutes of non-action period

Working Temperature

-10°C~+50°C,available

for as low as-20°C

on request

Size

153mm*76mm*37mm (H*W*D)

Weight

280g including batteries

Standard Package

UM-5 thickness gauge unit

Standard Probe (PT-08)

Carrying Case

Two 1.5V AA batteries

Couplant

Operating Mannual

Accessories

Numerous special probes;step

calibration;

Couplant and Hight temperature Couplant |

|