|

|

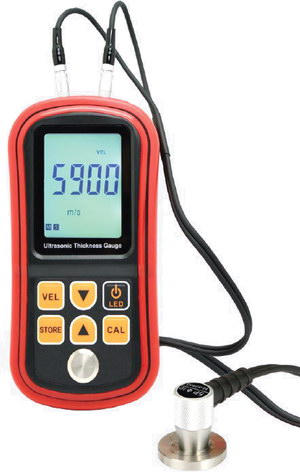

SR1851 Ultrasonic Thickness Gauge

Features

Auto Calibration to assure the accuracy

Auto linear compensation: this advanced

software program enhances the precision by correcting the non-linear

accuracy of transducer

Use "up" and "down" keys to make a quick

adjustment for the sound velocity/thickness and a quick recall to

the stored data

Coupling status indication: Observing

the coupling icon to learn if the coupling is accomplished or not

10 thickness measurement storage and

recall function available, which facilitated the height work or

working in wild area

Sound velocity measurement: with a given

thickness by a sample hardware to measure the sound velocity, which

avoid the further conversion or consultation of the table

12 sound velocity for different material

which also adjustable

Low battery indication

Auto power off mode designed to conserve

battery life

More than 10000 times long life keys

The unit has a special memory that

retains all of its setting even when the power is off

Specifications

LCD Digital display: 4 digits

Minimum display unit: 0.01 mm

Working frequency: 5 MHz

Measurement Range: 1.20 ~ 300.00 mm

(Steel)

Minimum limit for Tubes measurement:

¦µ20mm x 3mm (Steel)

Accuracy: ¡À (1% H + 0.05 mm) (H

denotes the measured thickness)

Sound Velocity Range: 1000 ~ 9999 m/s

Measuring Sound Velocity with a given

thickness

Measuring Range: 1000 ~ 9999 m/s

When the given thickness over 20mm, the

accuracy is ¡À1%; when the given thickness less than 20mm, the

accuracy is ¡À5%

Operating Temperature: 0 ~ 40 ¡ãC (32 ~

104 ¡ãF)

Power supply: 3 x 1.5 AAA Alkaline Batteries

Operation Current:

Normal Operation Current ¡Ü 50 mA

With Backlight turn on current ¡Ü 120 mA

Stand-by Current: ¡Ü 20 ¦ÌA

Item Dimensions: approx. 72 (L) x 146

(W) x 29 (H) mm (2.83 x 5.75 x 1.14 inch)

Item Weight: approx. 202 g (7.12 oz)

(Batteries and probe included) |

|

¡¡ |

¡¡ |

|

|

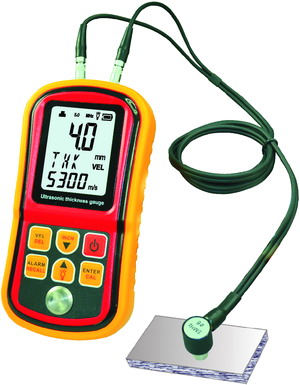

SR1860 Ultrasonic Thickness Gauge

Features

Auto Calibration to assure the accuracy

Auto linear compensation: this advanced

software program enhances the precision by correcting the non-linear

accuracy of transducer

Use "up" and "down" keys to make a quick

adjustment for the sound velocity/thickness and a quick recall to

the stored data

Coupling status indication: Observing

the coupling icon to learn if the coupling is accomplished or not

10 thickness measurement storage and

recall function available, which facilitated the height work or

working in wild area

Sound velocity measurement: with a given

thickness by a sample hardware to measure the sound velocity, which

avoid the further conversion or consultation of the table

12 sound velocity for different material

which also adjustable

Low battery indication

Auto power off mode designed to conserve

battery life

More than 10000 times long life keys

The unit has a special memory that

retains all of its setting even when the power is off

Specification

*Measuring range: 1.2~300mm (Steel)

*Accuracy: ¡À(1%H+0.1) mm

*Resolution: 0.01mm

*Sound velocity range: 1000~9999m/s

*Working frequency: 5MHz

*Minimum limit for tube measuring:

10mm probe: ¦µ20*3mm (Steel)

6mm probe: ¦µ12*2mm (Steel) (optional)

*Auto calibration to assure the accuracy

*Auto linear compensation: this advanced software program enhances

the precision by correcting the non-linear accuracy of transducer.

*Data store/ Data recall/ Data delete function

*Sound velocity measurement

*Low battery indication *Auto power off

*LCD backlight display

*Packing Method: Gift box + PP box

*Power supply: 3pcs*1.5V AAA alkaline batteries

*Weight: 210g *Dimension: 70*145*28mm

Include:

Ultrasonic thickness

gauge x 1, 5MHz/10mm probe x 1

5MHz/6mm probe x 1, Standard sample block:4mmx1

Carrying case x 1, Manual x 1 |

|

¡¡ |

¡¡ |

|

¡¡

¡¡

¡¡

Applications:

Used for measuring thickness and

corrosion of pressure vessels, chemical equipment, boilers, oil

storage tanks, etc. in industries of petroleum, shipbuilding, power

station, and machine manufacturing. |

SR1840 (0.9~400mm) Ultrasonic Thickness

Meter

Features:

* Using the latest high performance and

low power consumption microprocessor technology.

* Automatic memory material code and sound velocity value,

convenient to use.

* Use ¡°USB data output¡± to connect with PC.

* Provide ¡°Bluetooth ™ data output¡± choice.

Specifications:

|

Display |

4 Digit, 10 mm LCD |

|

Operating Principle |

Ultrasonic |

|

Measuring Range (metric / Imperial) |

0.75~400mm (45# steel) (Depend on Probe) |

|

Battery Indication |

Low Battery Indication |

|

Sound Velocity |

1000~9999 m/s |

|

Lower Limit Steel Pipes |

¦µ15*2.0 mm, ¦µ20*3.0 mm

determined by transducer |

|

Calibration Block |

Included |

|

Resolution |

0.1mm / 0.01mm / 0.001inch |

|

Accuracy |

¡À (0.5%n + 0.1) |

|

Automatic memory material code and the value of sound

velocity |

|

Power off |

Auto Power off & Manual Power Off |

|

Operating Conditions |

Temperature: 0~40 ¡ãC, Humidity: < 85 %RH |

|

Power Supply |

4*1.5

V AAA (UM-4) Battery |

|

Dimensions |

140*72*34 mm |

|

Weight |

185g (Not Including Batteries) |

Standard Accessories:

1. Main Unit

2. 5M§¶8 Standard Sensor

3. Coupling Agent

4. Carrying Case

5. Operating Manual

Optional Accessories:

1. 6M ¦µ6 mm thin Material Probe:

Measuring range (steel): 1.0~50.0 mm, Operating

temperature: -10~60¡ãC

2. 5M ¦µ12 mm High Temperature Probe:

Measuring range (steel): 1.0~225.0 mm (normal

temperature),

Measuring range (steel): 4.0~100.0 mm (high

temperature), Operating temperature: -10~300¡ãC

3. Curved Surface Probe

4. USB data cable with software

5. Bluetooth data output with software |

|

¡¡ |

¡¡ |

|

¡¡

¡¡

¡¡

¡¡

¡¡

¡¡

Applications:

Used for measuring thickness and

corrosion of pressure vessels, chemical equipment, boilers, oil

storage tanks, etc. in industries of petroleum, ship building, power

station, and machine manufacturing. |

SR1818 (0.9~400mm) Ultrasonic Thickness

Meter

Features:

* Using the latest high performance and

low power consumption microprocessor technology.

* Bidirectional measurement, for materials within measurement range,

thickness is measurable with know velocity, Conversely velocity is

measurable with know thickness.

* Automatic memory material code and sound velocity value,

convenient to use.

* Coupling symbol indication.

* Automatic power off to conserve power.

* Use "USB data output" to connect with PC.

* Provide "Bluetooth ™ data output"

choice.

Specifications:

|

Case Material |

Aluminum Alloy |

|

Display |

4 Digit LCD |

|

Operating Principle |

Ultrasonic |

|

Measuring Range (metric

/ Imperial) |

0.9~400 mm (45 # steel) |

|

Battery Indication |

Low Battery Indication |

|

Sound Velocity |

1000~9000 m/s |

|

Lower Limit Steel Pipes |

¦µ20 * 3.0 mm |

|

Calibration Block |

Included |

|

Resolution |

0.01 mm / 0.1

mm |

|

Accuracy |

¡À (0.5%n + 0.1) |

|

Automatic memory

material code and the value of sound velocity |

|

Power off |

Auto Power off & Manual

Power Off |

|

Operating Conditions |

Temperature: 0~40¡ãC,

Humidity: < 85 %RH |

|

Power Supply |

2 * 1.5 V AA (UM-3)

Battery |

|

Dimensions |

130 * 76 * 31 mm |

|

Weight |

340g (Not Including

Batteries) |

Standard Accessories:

1. Main Unit

2. 5M §¶8 Standard Sensor

3. Coupling Agent

4. Carrying Case

5. Operating Manual

Optional Accessories:

1. 6M ¦µ6 mm thin Material Probe : Measuring range (steel): 1.0~50.0

mm Operating temperature: -10~60¡ãC

2. 5M ¦µ12 mm High Temperature Probe: Measuring range (steel):

1.0~225.0 mm (normal temperature) Measuring range (steel) :

4.0~100.0 mm (high temperature) Operating temperature: -10~300¡ãC

3. Curved Surface Probe

4. USB data cable with software

5. Bluetooth data output with software |

|

¡¡ |

¡¡ |

|

|

SR1911 High-precision Ultrasonic Thickness

Gauge

Handy, precise,

excellent EMC performance

Instrument Features:

Embedded Bluetooth module, supporting wireless report printing

USB2.0 interface

Achieve precise thickness measurement by using high-precision timing

chip

Displaying accuracy of the test result is 0.001mm

Intelligent voice broadcasting of result readings

The brightness and the contrast of the LCD is adjustable

Main Functional Parameters:

1. Adapted to measure the thickness of

good conductor for ultrasonic, such as metal (steel, cast iron,

aluminum, copper), plastic, ceramic, glass, glass fiber and so on.

2. Match with a series of probes with various frequency and crystal

size.

3. Automatic zero adjustment, two-point correction and auto

correcting system errors.

4. Able to measure the ultrasonic velocity in turn if the thickness

value is known in order to improve the measurement precision.

5. Two working modes: single point measurement and scanning

measurement.

6. Able to preset the upper limit and the lower limit for the

thickness, alarm when the value is beyond the limit.

7. Coupling state indicating in the display.

8. With LED backlight of display, easily used in dark environment.

9. Indicating remaining battery energy on the LCD for the real-time

power energy monitoring .

10.Able to communicate with the PC via USB interface

11. Wireless printing with Embedded wireless module

12. Standard delivery equipped with PC software+USB

cable properly, sending the

measurement results, managing the measurement store, analyzing the

measurement statistics, printing the measurement reports and so on.

13. Adaptive in poor operating environment, compatible with

vibrating, impact, and electromagnetic interference.

¡¡ |

|

Specification |

Model |

SR1911 |

|

Measuring range |

Metric Imperial |

0.75-300mm(steel) |

|

Operating principle |

Ultrasonic |

|

Displaying accuracy |

0.001mm |

|

Measuring error |

1 mm~10 mm:+/-0.03mm; 10mm~300mm:(+/-0.3%H+0.03)mm |

|

Measurement period |

fourth per second |

|

Measurement frequency |

5MHZ |

|

Ultrasonic velocity |

1000-9999m/s |

|

Display |

FSTN digital LCD with cold back light |

|

Zero adjustment |

auto returning |

|

Linear correction |

auto linear correction by the MCU programs (V Path

auto-compensation) |

|

Alarm function |

setting the measurement limit and alarming for the results

beyond the limit |

|

Data memory |

1000 readings |

|

Working voltage |

3.7V Lithium Battery |

|

Power off |

Auto power off if not working for 2 minutes, and the power

key is also available |

|

Display contents |

thickness value, coupling state, power state, CAL

calibration state, sound velocity |

|

Dimensions |

132x76.2x28mm |

|

Whole weight |

323g |

|

Standard delivery |

Main unit |

1 |

|

Instruction manual |

1 |

|

Carrying case |

1 |

|

equipped with PC software+ USB cable |

1 |

|

|

¡¡ |

¡¡ |

|

|

|

|

SR1200 (0.75 to 300mm)

Ultrasonic Thickness Gauge

-Durable metal shell

-LCD matrix display with backlight

-Mini-thermal printer for fast on-site printing

-Wide measuring range:0.75-300mm (in Steel)

-Sound Velocity Range: 1000~9999 m/s

-Display resolution:0.1/0.01mm (selectable)

-Accuracy:+-(0.5%Thickness+0.04)mm

-Software to analysis tested results

-Units: mm/inch selectable

¡¡

¡¡

Product information:

Metal case, dox matrix

LCD (menu operation)

Ultrasonic Thickness Gauges are designed to improve safety and

ensure reliability of material subject to corrosion or erosion.

Corrosion gauges with their dual-element transducers are the primary

inspection tool used to measure the remaining walls of components

such as pipelines, pressure vessels, storage tanks, and numerous

other applications..

Precision gauges use single-element transducers to provide the

thinnest range and highest degree of accuracy possible. Common

applications include metals and a variety of non-metals (i.e. glass,

ceramic, plastic, etc.)

Specifications:

|

Measuring Range |

0.75mm-300mm(in steel) |

|

Sound Velocity |

1000~9999 m/s |

|

Resolution |

0.1/0.01mm (selectable) |

|

Units |

mm/inch (selectable) |

|

Storage |

20 groups (100 files / group) |

|

Accuracy |

¡À ( 0.5%Thickness+0.04 ) mm |

|

Alarm |

preset upper and lower limit |

|

Work voltage |

3V( 2 AA alkaline batteries) |

|

Interface port |

RS232 |

|

Dimensions |

132mm*76mm*33mm |

|

Weight |

345g |

|

Display |

LCD with backlight |

|

Continuous working period |

100 hours (with backlight off) |

|

Standard Deliveries: |

|

Optional Deliveries: |

|

No |

Items |

Qty |

|

No |

Items |

Qty |

|

1 |

Main unit |

1 |

|

1 |

N02 probe |

1 |

|

2 |

N05/90 probe |

1 |

|

2 |

N07 probe |

1 |

|

3 |

Couplant |

1 |

|

3 |

NHT5 probe |

1 |

|

5 |

Instruction manual |

1 |

|

4 |

N05 probe |

1 |

|

6 |

Warranty card |

1 |

|

5 |

Datapro |

1 |

|

7 |

Carrying case |

1 |

|

6 |

Mini-printer |

1 |

|

9 |

Cables |

1 |

|

7 |

printer cable |

1 |

|

10 |

Batteries |

4 |

|

8 |

Communication cable |

1 |

|

SR1160 (0.75 to 300mm)

Ultrasonic Thickness Gauge

-Capable of performing measurements on all ultrasonic sound

well-conductive materials: metals, plastic, ceramics,

composites, epoxies, glass, etc

-5 models of probe are available for coarse grain material and

high temperature thickness tests

-Resolution: 0.1/0.01mm (selectable)

-Two-Point Calibration function.

-Single point mode and Scan mode

-Coupling status indicator

-Software to analysis tested results on computer

-Optional thermal mini-printer to print the measured data via port

RS232

Product information:

Plastic case, Segement

LCD

Ultrasonic Thickness Gauges are designed to improve safety and

ensure reliability of material subject to corrosion or erosion.

Corrosion gauges with their dual-element transducers are the primary

inspection tool used to measure the remaining walls of components

such as pipelines, pressure vessels, storage tanks, and numerous

other applications..

Precision gauges use single-element transducers to provide the

thinnest range and highest degree of accuracy possible. Common

applications include metals and a variety of non-metals (i.e. glass,

ceramic, plastic, etc.)

Specifications:

|

Measuring Range |

0.75mm-300mm(in steel) |

|

Sound Velocity |

1000~9999 m/s |

|

Resolution |

0.1mm/0.01mm selectable |

|

Units |

mm/inch (selectable) |

|

Memory |

20 groups (100 files / group) |

|

Accuracy |

¡À ( 0.5%Thickness+0.04 ) mm |

|

Alarm |

preset upper and lower limit |

|

Work voltage |

3V( 2 AA alkaline batteries) |

|

Work mode |

Single point and scan |

|

Interface port |

RS232 |

|

Dimensions |

150mm*74mm*33mm |

|

Weight |

245g |

|

Display |

LCD with backlight |

|

Continuous working period |

100 hours (with backlight off) |

|

Standard Deliveries: |

|

Optional Deliveries: |

|

No |

Items |

Qty |

|

No |

Items |

Qty |

|

1 |

Main unit |

1 |

|

1 |

N02 probe |

1 |

|

2 |

N05/90 probe |

1 |

|

2 |

N07 probe |

1 |

|

3 |

Couplant |

1 |

|

3 |

NHT5 probe |

1 |

|

5 |

Instruction manual |

1 |

|

4 |

N05 probe |

1 |

|

6 |

Warranty card |

1 |

|

6 |

Mini-printer |

1 |

|

7 |

Carrying case |

1 |

|

|

|

|

|

9 |

Cables |

1 |

|

|

|

|

|

10 |

Batteries |

4 |

|

|

|

|

|

|

¡¡ |

¡¡ |

|

SR1150 (0.75 to 300mm)

Ultrasonic Thickness Gauge

-Resolution: 0.1mm

-Test thickness of all ultrasonic well conductible materials

-Four probes available for special needs

-Probe-Zero function and Sound-Velocity-Calibration function

-Two-Point Calibration function

-Single point mode and Scan mode

-Coupling status indicator showing the coupling status

-Auto sleep and auto power off function

-Software to analysis the storage data on the PC

Product information:

Plastic case, Segement

LCD

Ultrasonic Thickness Gauges are designed to improve safety and

ensure reliability of material subject to corrosion or erosion.

Corrosion gauges with their dual-element transducers are the primary

inspection tool used to measure the remaining walls of components

such as pipelines, pressure vessels, storage tanks, and numerous

other applications..

Precision gauges use single-element transducers to provide the

thinnest range and highest degree of accuracy possible. Common

applications include metals and a variety of non-metals (i.e. glass,

ceramic, plastic, etc.).

Specifications:

|

Measuring Range |

0.75mm-300mm(in steel) |

|

Sound Velocity |

1000~9999 m/s |

|

Resolution |

0.1mm |

|

Units |

mm/inch (selectable) |

|

Memory |

20 groups (100 files / group) |

|

Accuracy |

¡À ( 0.5%Thickness+0.04 ) mm |

|

Alarm |

preset upper and lower limit |

|

Work voltage |

3V( 2 AA alkaline batteries) |

|

Work mode |

Single point and scan |

|

Interface port |

RS232 |

|

Dimensions |

150mm*74mm*33mm |

|

Weight |

245g |

|

Display |

LCD with backlight |

|

Continuous working period |

100 hours (with backlight off) |

|

Standard Deliveries: |

|

Optional Deliveries: |

|

No |

Items |

Qty |

|

No |

Items |

Qty |

|

1 |

Main unit |

1 |

|

1 |

N02 probe |

1 |

|

2 |

N05/90 probe |

1 |

|

2 |

N07 probe |

1 |

|

3 |

Couplant |

1 |

|

3 |

NHT5 probe |

1 |

|

5 |

Instruction manual |

1 |

|

4 |

N05 probe |

1 |

|

6 |

Warranty card |

1 |

|

|

|

|

|

7 |

Carrying case |

1 |

|

|

|

|

|

9 |

Cables |

1 |

|

|

|

|

|

10 |

Batteries |

4 |

|

|

|

|

|

SR1098 (0.75 to 300mm)

Ultrasonic Thickness Gauge

-Resolution: 0.1mm

-Test thickness of all ultrasonic well conductible materials

-Four probes available for special needs

-Probe-Zero function and Sound-Velocity-Calibration function

-Two-Point Calibration function

-Single point mode and Scan mode

-Coupling status indicator showing the coupling status

-Auto sleep and auto power off function

Product information:

Plastic case, Segement

LCD

Ultrasonic Thickness Gauges are designed to improve safety and

ensure reliability of material subject to corrosion or erosion.

Corrosion gauges with their dual-element transducers are the primary

inspection tool used to measure the remaining walls of components

such as pipelines, pressure vessels, storage tanks, and numerous

other applications..

Precision gauges use single-element transducers to provide the

thinnest range and highest degree of accuracy possible. Common

applications include metals and a variety of non-metals (i.e. glass,

ceramic, plastic, etc.).

Specifications:

|

Technology parameter

|

|

Model |

SR1098 |

|

Operating principle |

Ultrasonic |

|

Measure range |

0.75~300mm(determined by probe) |

|

Accuracy |

¡À (0.5%H+0.1)mm |

|

Sound velocity |

1000~9999m/s |

|

Lower limit steel pipes |

¦Õ20mm*3.0mm(5MHz), ¦Õ15mm*2.0mm(10MHz) |

|

To measure velocity by thickness |

|

Measure range |

1000~9999m/s |

|

Thickness of the measured sample |

¡Ý20mm (Accuracy: ¡À5%) |

|

Power |

DC1.5V¡Á2 |

|

Environment temperature |

0ºC~40ºC |

|

Relative humidity |

¡Ü85% |

|

Dimension |

150mm*73mm*32mm |

|

Weight (Not including battery) |

400g |

|

Materials measured |

Any hard materials, including steel, Cast iron, Aluminum,

Red copper, Brass, Zinc, Quartz glass, Gray cast iron and

other materials. |

|

Standard Delivery |

Main unit 5M¦Õ10 transducer Couplant Instruction manual

Carrying case |

|

|

¡¡ |

¡¡ |

|

¡¡ |

¡¡ |